DIN 75220 Electric Vehicle Solar Simulation Test Chamber Halogen Lamp Test Chamber

|

|

DIN 75220 Electric Vehicle Solar Radiation Halogen Lamp Test Chamber

Complied Standards & Clauses

DIN 75220: “Ageing Automobile Components in Solar Simulation Units” ISO9060:2007 “Solar energy-Specification and classification of instruments for measuring hemispherical solar and direct solar radiation” ISO 12097-2: "Road vehicles-Airbag components-Part 2: Testing Of airbag modules"

Technical Parameters

Equipment Overview

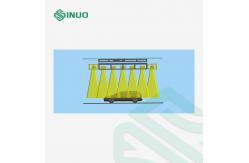

Lighting System The system is composed of intelligent control power supply, optimized design of reflector lamp housing, Osram 2500W metal halogen lamps, cabinet, illuminance meter, etc. It can perfectly simulate the sunlight irradiation environment under various conditions. Coupled with environmental factors such as temperature, humidity, rain, and snow, it is used to evaluate the impact of direct solar radiation on the test specimen (thermal, mechanical, chemical, electrical, etc.), and can also be used to reveal the mutual interaction between different materials in the component effect. The sunlight simulation system can be used alone for testing of electronics, materials, and small-volume test pieces. Multiple sets of systems can also be combined into a light array through professional design and layout, which is used for the test of cars, trucks, photovoltaic modules, even trains and airplanes.

Intelligent power supply (EPS):

1) The power module uses a high-performance MCU as the control core, and the high-precision vector control algorithm ensures a stable output of energy, so that the brightness of the lamp is fixed and is not affected by the input grid voltage and cooling.

2) It can realize 20% to 100% output stepless adjustment, the overall heat dissipation is small, and it has multiple control and communication methods.

3) The power supply control can monitor the status of the lamp in real time during the lighting process and make corresponding warnings. If the lighting is unsuccessful, it will stop the lighting and give an alarm prompt when it exceeds a certain delay, avoiding the dangerous situation of unsuccessful lighting for a long time to maintain high voltage.

Cabinet:

Modular power supply design, with the overall cabinet, with advantages of small footprint, neat lines, convenient connection; power supply can be placed in the overall cabinet for unified control, provide corresponding communication interface protocol into the test box control system, and use the touch screen for system local control and operation, control accuracy: ≤5%.

Sunlight simulation: A total of 98 sets of light sources, each set of light sources is equipped with an EPS control power supply, which can control the power supply of each light source separately.

Full spectrum: +/- 10%, within a height of 1m.

Control System:

The lighting simulation system adopts closed-loop control mode, equipped with KIPP & ZONEN SMP10 high-sensitivity lighting sensor that meets ISO 9060 two-level standard. Through this sensor, the light intensity of the measured surface is collected in real time. The control system automatically adjusts the energy output according to the deviation between the set value and the collected value, to ensure the stability of the light throughout the test.

Advantages:

Wide operating environment Since there are no starter lamp electronic components in the reflector of the lighting system, the system has very wide temperature and humidity operating range (temperature range is -100 ℃ -200 ℃, humidity range is 0-98%).

High security Because the lighter is installed in the intelligent power supply, the intelligent power supply can monitor the working voltage and current of the metal halide lamp in real time., to ensure that the power supply is automatically stopped when the lamp is turned off and the lamp is not excited, and the alarm information is given. In addition, the device does not need to be discharged after use, to avoid negligent operation of high voltage electric shock. Comes with BUCK voltage regulator circuit and power vector control algorithm to control the output, effectively avoiding the phenomenon of light extinction caused by grid fluctuations. With fault alarm and automatic protection, there is no voltage at the output end when the light is off.

Good stability Comes with BUCK voltage regulator circuit, which can work at AC340V ~ 440V; The control system is controlled by power vector control algorithm to ensure the output power is constant and adjustable; with automatic compensation functions such as air extraction compensation, real-time monitoring of abnormalities and automatic adjustment, regardless of voltage fluctuations and ambient temperature fluctuations, the output energy is still constant; comprehensive safety protection: lamp parameter error protection, lamp disconnection protection, lamp short circuit protection, etc.; using German Siemens IGBT, Japanese magnetic core, American MCU. (Can work at 100 ℃); all equipment has passed 100% functional testing and aging process testing.

Wide adjustment range Microcomputer control, with automatic compensation functions such as ventilation compensation, real-time monitoring of abnormalities and automatic adjustment, so that the system has the ability to adjust from 10% -100% energy stepless. With linear control and square wave output, the highest efficiency is achieved, regardless of voltage fluctuations and ambient temperature fluctuations, the output energy is still constant.

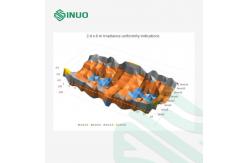

1. Sunlight simulation system This test system consists of a total of 98 sunlight simulation units (14 × 7). Each sunlight simulation unit has the same power and is 4KW. The specific distribution is as follows:

2. Effective area of irradiation: 1500×1500mm

3. Irradiation distance: 1200mm (fixed)

4. Average irradiation intensity: 1050W / m2 (Continuously adjustable within 600-1200W / m2, the modulation accuracy is not greater than 50W / m2. Can be used for low-irradiation experiments of 200W / m2. Due to the EPS is infinitely adjustable within the range of 50% -100%, for experiment of low-irradiation of 200W , the grating should be increased, and the radiation intensity controlled through the transmission rate of the grating (60%, 80% two specifications), so that the light intensity can reach 200W / m2).

5. Light support The lamp support is made of industrial aluminum profiles. Lampshade is made of aluminum magnesium alloy. There are 4 sets of lamp stands installed on the lamp support. The lamp stands are divided into 2 horizontal rows, 4 lamp tubes in each row, and each bulb is 2500W. The distance between the front, back, left, and right of the lamp tube is 1200MM, and each light bulb has an independent switch control. The layout of the light bulb is shown in the figures. The power adjustment range of the lamp is stepless adjustment within the range of 10% to 100%, the total power of the lamp is 10KW.

6. Light intensity sensor Three light intensity sensors are used to measure radiant power in

W / m².

The metal halide lamp intensity can be adjusted to 50% by EPS. If a low-irradiation test is required, it can be achieved by turning off the light source. 1120 W/m² electrically dimming

all lamps ON 55 W/m² Not possible Uniformity

7. Lighting control mode Automatic control through the light intensity feedback, also can be manually adjusted to the required intensity, and has the function of alarm / stop when the measured parameter value exceeds the limit.

8. Technical data System operating temperature range: -20 ° C to + 60 ° C Equipped with a computer (industrial computer)

Chamber Design Drawings

Questions & Answers

Q: What temperature can this device reach?

Q: What is the size for Irradiation area?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: evse solar simulation test chamber Electric Vehicle solar simulation test chamber DIN75220 ev Testing Equipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

IPX5 IPX6 Water Spray Test Chamber For Waterproof Testing Of Electronic Devices |

|

IEC 62196-1 Universal Material Tensile Machine for Insertion Test |

|

Tensile Strength Test Machine 10KN For Materials Test Bending Folding Test |

|

Gantry Type Tensile Test Equipment 5kN Compression Bending Test |

|

Wire Damage Testing Device Terminal Mechanical Stress Tester for Electrical Connectors |

|

Random Vibration Test System Sine Sweep Electromagnetic Vibration Testing Machine |