IPX3 IPX6 Water Spray Test Chamber Jet Nozzle IP Code Testing Chamber

|

|

IEC 60529 IPX3 to IPX6 Water Spray Jet Nozzle IP Code Testing Chamber

Complied Standards & Clauses

IEC60529:2013 “Degrees of protection provided by enclosure (IP code)” IP5 &IP6

Equipment Overview Use Environment: Power supply: AC220V±5%/50Hz, 10KVA, or match client’s local power supply requirements. Use place: temperature 15-35 ° C, relative humidity 25%-75%, atmospheric pressure 86 ~ 106kpa (860 mbar -1060 mbar), there should be equipped with lighting and waterproof leakage switch (or socket), the ground needs to be flat, and the water intake and drainage function should be good. Water source: clean water or tap water without impurities, equipped with water cleaning filter.

Samples and Restrictions: Electrical and electronic products, automobiles, motorcycle parts, household appliances, communication products, outdoor lighting and signal devices, etc.

Structure: The test equipment consists of a chassis, an oscillating tube water spraying mechanism, a water jetting mechanism, a tunnel, an electrical control cabinet and a turntable. The oscillating mechanism is installed in the middle of the inner chamber, two ends are fixed on the side walls of the inner chamber. The water jetting mechanism is located in the left side and connected to inner chamber through the long tunnel, which ensure the distance between the nozzle and the sample. The sample is placed on the turntable, the turntable is caused to rotating by motor driving at a rotation speed of 1r/min, to make the enclosure of the specimen to be splashed in all directions or sprayed from all practicable directions; and the height of the turntable can be adjuted manually, to match the test distance from needle to the sample. This whole system is equipped with a water filtration cleaning device to prevent pinhole blockage. And the test system adopts the chamber type structure.

Application: To verify the protective performance of the enclosure for electronic and electrical products, automobiles, motorcycle parts, household appliances, seals and lamps under water spraying and splashing at degree IPX3 & IPX4 and water jets at degree IPX5 and IPX6.

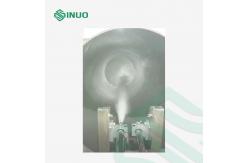

Principle: Ensure that the water spray and water jet speed reach the standard required value by controlling the water supply flow, make the enclosure of the specimen to be splashed in all directions or sprayed from all practicable directions.

Technical Parameters

|

||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: IPX3 IPX6 water spray test chamber IPX4 IPX5 water spray test chamber Jet Nozzle ip test equipment | ||||||||||||||||||||||||||||||||||||||||||||||

|

Corrosion Test Equipment Salt Fog Test System for Automotive Components |

|

DO-160G Civil Aviation Electronics Anti-Drip Waterproof Test Chamber |

|

Waterproof Testing Equipment IP Test Equipment IPX7 Immersion Test Chamber |

|

Oscillating Tube Water Spray Tester IPX3 IPX4 Waterproof Test System |

|

IPX5 IPX6 Automotive Parts Water Resistance Tester IP Code Test Equipment |

|

IPX7 Waterproof Test Chamber Waterproof Performance Testing Machine |