IEC 60086-4 Battery Test Machine Lithium Batteries Fire Explosion Testing Equipment

|

|

IEC 60086-4 Battery Test Machine Lithium Batteries Fire Explosion Testing Equipment

Complied Standards & Clauses IEC60086-4:2014 Primary batteries –Part 4: Safety of lithium batteries clause 6.2.5 & 6.2.7 figure 1 UL 2580 Batteries for Use In Electric Vehicles Annex B2.10 and D3.10 UL 1642 BATTERIES FOR USE Lithium Batteries Clause 20 FIG. 20.1 UL 2054 Advantage for Battery Packs Clause 22 FIG. 22

Technical Parameters

Equipment Overview 1 Product Overview

1.1 Applied standards This apparatus conforms to IEC60086-4:2014 FIG 1, UL2054 Clause 22 FIG. 22.1, UL 1642-2009 Clause 20 FIG. 20.1, GB 31241-2014 Article 7.9 FIG. E.2.

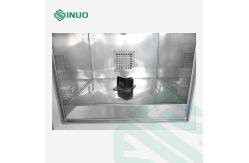

1.2 Application Battery Fire Exposure Test Apparatus is an essential test equipment for battery manufacturers and quality inspection departments. This equipment has the characteristics of convenient operation, safety and reliability, and high precision. It is an ideal testing machine for battery combustion and projectile testing.

1.3 Features 1.3.1 PLC and touch screen for control and operation. 1.3.2 When there is a smoke alarm, the exhaust will automatically open, and when there is no smoke, it will be closed after a delay. 1.3.3 Unsuccessful ignition alarm and cut off steam source. 1.3.4 Built-in lighting, through external reflection, to ensure the life and safety of lighting, etc. 1.3.5 The HD video camera and visual window can enable operator to clearly observe the changes of the test object in the experiment. 1.3.6 With explosion-proof glass, and equipped with steel mesh, double protection. 1.3.7 Controlled by remote controller, the maximum distance can reach 10 meters.

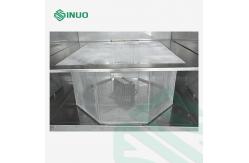

1.4 Test procedures The test battery is placed on a flat table covered with a cover plate with a 4-inch diameter hole in the middle. Cover plate is made of steel wire mesh with 20 holes per foot or steel wire 0.017 inch (0.43mm). Place a screen with 8 sides of 2 feet wide (610 mm) and 1 foot high (305 mm) on each side around the specimen. The metal mesh consists of 0.010-inch (0.25mm) metal wire at 16-18 wires per inch. The sample is placed on a metal mesh, covering the hole in the center of the table, and then heated until it explodes or is destroyed. The direction of the safety valve is parallel to the asbestos cloth.

Acceptance: No part of the explosive battery penetrates the screen, and no part or all of the battery protrudes from the screen.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: UL2054 lithium ion battery testing equipment UL2580 lithium ion battery testing equipment UL2580 Fire Exposure Test Equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Battery Explosion-proof Test Chamber Lithium Battery Safety Test Equipment |

|

IEC 62133 Battery Testing Lithium Battery Drop Test Machine 1500mm |

|

UN38.3 Lithium Battery Safety Testing Heavy Impact Test Machine |

|

IEC62133 Battery Test Equipment Explosion-proof Chamber for Lithium Battery Testing |

|

SAE J2464 Battery Crush And Nail Penetration Test Equipment 300kN |

|

EV Battery Testing Equipment Temperature And Humidity Test Chamber 5℃ Nonlinearity |