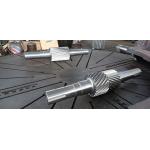

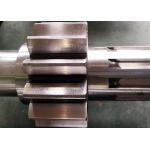

Working Principle of Transmission Gear Shaft Enhancing Efficiency with Involute Tooth Profile

|

|

1) Descriptions of Transmission Gear Shaft Precision components processed by turning, hobbing, grinding and other processes are required to ensure the coaxiality of gears and shafts. 2) Features of Transmission Gear Shaft a) Complex process: requires multiple processes (e.g. heat treatment, finishing). b) Strong customisation: modulus, tooth shape and other parameters can be designed according to requirements. c) Controllable cost: mass production can reduce the unit price. 3) Working Principle of Transmission Gear Shaft The involute tooth profile of the gears ensures that sliding friction is minimised during meshing, enhancing efficiency. 4) Application of Transmission Gear Shaft Industrial robots, power tools, automated production lines, etc.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: CNC Machining Transmission Gear Shaft Involute Tooth Profile Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Custom-made SAE 4340 Steel Transmission Spare Parts Helical Gear Shafts |

|

SAE 4340 Steel Left Hand Helical Gear Shaft DP 1.5 24T Angle 5° |

|

Helical Spline Transmission Gear Shaft 18CrNiMo7 Forged Steel |

|

Transmission Gears DIN 17CrNiMo6 Forging Steel Helical Gear Driven Shaft |

|

Carburizing Transmission Gear Shaft Spline Shafts For Gear Reducers |

|

Carburizing Heat Treatment for Enhanced Strength and Durability of Transmission Gear Shaft |