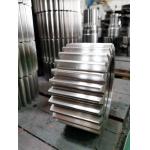

45° Helical Angle 2 Module Transmission Gears Precision Manufacturing

|

|

2-module Power Skiving internal helical gears 45° helical angle 1) Description of Internal Helical Gear Internal helical gears are a special type of gear with a helical tooth shape and machined on the inner surface of a cylindrical member, meshing with an external helical gear to achieve power transmission. Compared with spur internal gears, its spiral tooth design has advantages in transmission performance, load capacity, and noise control, and is widely used in industrial scenarios that require compact layout and efficient power transmission. 2) Key Features of Internal Helical Gear a) High transmission stability to the next, reducing shock and vibration and operating noise. to withstand higher radial and axial loads than spur internal gears

of the same specification, making them suitable for high-torque

scenarios. while the helical design further optimizes the axial dimensions for

compact equipment . 3) Applications of Internal Helical Gear a) Industrial gearbox: used for deceleration or speed increase

transmission of metallurgical and mining equipment, transmitting

high power torque.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 45° Helical Angle Transmission Gears Transmission Gears Precision Manufacturing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 Module 26T Grinding Planet Gear For Coal Mining Machinery |

|

Customized Forging Alloy Steel Spur Gear 12 Module 20Cr2Ni4 For Mining Machinery |

|

16 Module 15T Gear Grinding Metal Spur Gear With Straight Sided Spline |

|

20Cr2Ni4 Ground Planetary Driven Metal Spur Gear ISO 7 Grade |

|

Ground Sun Metal Spur Gear 10 Module 12T For Planetary Reducer |

|

14 Module 17T Planetary Drive Metal Spur Gear Rectangular Spline |