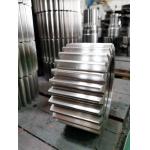

Straight 10 Module 32 Tooth Spur Gear For Mining Transmission System

|

|

10 Module 32T Gear Grinding Spur Gears For Mining Transmission System 1) Material of Spur Gear Spur gears can be made from metals such as steel or brass, or from plastics such as nylon or polycarbonate. Gears made of plastic produce less noise, but at the expense of strength and loading capability. Unlike other gear types, spur gears don’t experience high losses due to slippage, so they generally have high transmission efficiency. Multiple spur gears can be used in series (referred to as a gear train) to achieve large reduction ratios. 2) Applications of Spur Gear Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment. Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as washing machines and blenders. And while noise limits the use of spur gears in passenger automobiles, they are often used in aircraft engines, trains, and even bicycles.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 10 Module 32 Tooth Spur Gear Transmission System 32 tooth spur gear 32T straight tooth spur gear | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 Module 26T Grinding Planet Gear For Coal Mining Machinery |

|

Customized Forging Alloy Steel Spur Gear 12 Module 20Cr2Ni4 For Mining Machinery |

|

16 Module 15T Gear Grinding Metal Spur Gear With Straight Sided Spline |

|

20Cr2Ni4 Ground Planetary Driven Metal Spur Gear ISO 7 Grade |

|

Ground Sun Metal Spur Gear 10 Module 12T For Planetary Reducer |

|

14 Module 17T Planetary Drive Metal Spur Gear Rectangular Spline |