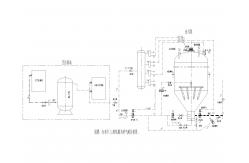

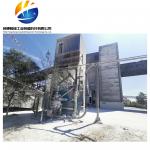

PCD Powder Pneumatic Conveying System Dense Phase

|

|

PCD Type Conventional Positive Pressure Dense Phase Pneumatic Conveying Silo Pump

Description PCD type positive pressure dense phase pneumatic conveying warehouse pump Hengcheng company has developed pneumatic conveying equipment and process system with independent intellectual property rights after years of research and rich practical experience, and its main indicators have reached the international advanced level. The volume of the pump is determined according to the nature, particle size, conveying distance and conveying volume of the conveyed material, that is, a stand-alone design is carried out, so that the conveying energy consumption can be minimized on the premise of meeting the technological requirements. According to the specifications and performance of powder materials, conveying distance, conveying volume and geographical conditions and other parameters provided by customers, we formulate the best plan for pneumatic conveying, including the calculation of air volume, the ratio of pipelines, the dust collection treatment of the receiving bin and the after-sales plan Wait.

Conventional Grid Pneumatic Conveying Bin Pump Parameter Table

Product main features

Application field

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: PCD powder pneumatic conveying system Dense Phase powder pneumatic conveying system PCD pneumatic conveying system for powder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pneumatic Ejector Pump For Powder & Bulk Solids – High Efficiency Air-Powered Dilute Phase Conveyor |

|

Industrial Dense Phase Conveying Pump System - Low Maintenance Fly Ash Handling System |

|

High-Quality Pneumatic Conveying Pump Air Conveying Pump For Bulk Material Handling |

|

Dense Phase Vessel Pump System for Cement Powder 0.5-50TPH Capacity |

|

Dense Phase Pneumatic Conveying Pump for Cement & Powder – Dust-Free Solution |

|

Powder Transport Medium Customizable Dense Phase Pneumatic Conveying Silo Pump Advanced Powder Conveying System |