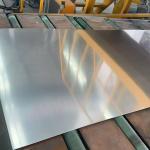

TISCO 2205 Duplex Stainless Plate 1.4462 S31803 ASTM A240

|

|

TISCO Stainless Steel Plate Grade 2205 Duplex Stainless Steel 1.4462 / S31803 ASTM A240

Specification of our 2205 duplex stainless steel plate

Duplex Stainless Steel 2205 (UNS S31803) Pipes, Tubes, Fittings, Flanges, Fasteners, Plates and Bar : Agent, Exporter, Dealer, Distributor, Stockist, Stockholder and Supplier in India :Mechanical Properties of duplex 2205 stainless steel

Chemical Composition of duplex 2205 stainless steel

Alloy Designations of duplex 2205/1.4462 Stainless SteelGrade 1.4462/2205 is similar to: UNS S31803 Supplied Forms

Duplex 2205 stainless steels are typically used in:

Corrosion Resistance

Duplex stainless steels are extremely corrosion resistant. They have high resistance to intergranular corrosion. Even in chloride and sulphide environments, duplex stainless steels exhibit very high resistance to stress corrosion cracking. The super duplex grades are even more resistant to corrosion.

Heat Resistance

The high chromium content of duplex stainless steels that protects against corrosion, causes embrittlement at temperatures over about 300°C. At low temperatures duplex stainless steels have better ductility than the ferritic and martensitic grades. Duplex grades can readily be used down to at least -50°C.

Fabrication

Fabrication of all stainless steels should be done only with tools dedicated to stainless steel materials. Tooling and work surfaces must be thoroughly cleaned before use. These precautions are necessary to avoid cross contamination of stainless steel by easily corroded metals that may discolour the surface of the fabricated product.

Machinability

Although machinable, the high strengths of duplex stainless steels makes machining difficult. As an example, machining of 2205 is around 20% slower than for 304. Machining can be enhanced by using the following rules: ~ Cutting edges must be kept sharp. Dull edges cause excess work hardening. ~ Cuts should be light but deep enough to prevent work hardening by riding on the surface of the material. ~ Chip breakers should be employed to assist in ensuring swarf remains clear of the work ~ Low thermal conductivity of austenitic alloys results in heat concentrating at the cutting edges. This means coolants and lubricants are necessary and must be used in large quantities.

Heat Treatment

Duplex stainless steels cannot be hardened by heat treatment. They can however be work hardened. Solution treatment or annealing can be done by rapid cooling after heating to around 1100°C.

Weldability

Duplex stainless steels have good weldability. All standard welding processes can be used. They are not quite as easily welded as the austenitic grades but low thermal expansion in duplex grades reduces distortion and residual stresses after welding. The recommended filler material for 2205 stainless steel is 2209.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 2205 duplex stainless plate TISCO duplex stainless plate A240 duplex steel sheet |

|

High-Performance 317L Stainless Steel Plate Alloy 317L SS Plate 1219mm 1500mm 2000mm Width |

|

317L Stainless Steel Plate Sheet 2B NO.1 Surface 0.6 - 30.0mm With 4ft*8ft and 5ft*20ft |

|

ASTM A240 317l / S31703 / 1.4438 Stainless Steel Plate , Stainless Steel Sheet With 3.1 Certificate |

|

317L / S31703 Stainless Steel Plate Cold Rolled and Hot Rolled 0.6 - 30.0mm from TISCO |

|

654SMO Stainless Steel Plate (UNS S32654, 1.4652) SS PlateThickness 1.0 - 80.0mm |

|

High Purity 654SMO Stainless Steel Plate For Chemical, Marine, Power Generation Sectors |