Product Description:

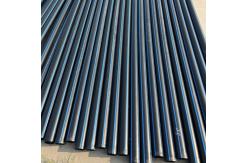

Our Dredging HDPE Pipe is made of high-density polyethylene (HDPE)

PE100/PE80 material, providing excellent resistance to chemicals,

corrosion, and abrasion. This makes it a suitable choice for harsh

mining environments where other materials may not be able to

withstand the pressure.

With each length measuring 5.8/11.8m, our Dredging HDPE Pipe is

easy to install and maintain, saving you time and effort in the

long run. The heavy-duty wear-resistant material ensures that it

can handle the most demanding mining applications with ease, making

it a reliable and cost-effective solution.

Whether you are looking for a slurry pipe for your mining

operations or a durable pipeline for dredging purposes, our

Dredging HDPE Pipe is the perfect choice. Its abrasion resistance

and high-quality production standards make it a reliable and

long-lasting option for your mining needs.

Features:

- Product Name: Dredging HDPE Pipe

- Pressure: 0.4~2.0Mpa

- Flexibility: High Flexibility

- Application: Mining

- Connection: Fusion Welding, Steel Flanges

- Thickness: Customized

- HDPE pipe with stub

- Slurry pipe

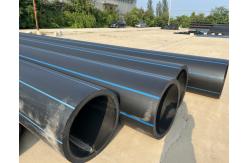

- DN500 HDPE pipeline

Technical Parameters:

| Technical Parameter | Value |

|---|

| Diameter | Customized(Dia32-1800mm) |

| Color | White With Blue Strips |

| Material | HDPE PE100/PE80 |

| Length | 5.8/11.8m Per Length |

| Production method | Extruding |

| Application | Mining |

| Accessories | Bolts Nuts And Washers |

| Connection | Fusion Welding, Steel Flanges |

| Production standard | ISO4427 |

| Corrosion Resistance | Stable Corrosion Resistant Ability |

Applications:

The Jiubei DN200 HDPE pipe is a heavy-duty wear-resistant product

that is widely used in dredging operations. It is made in China and

has been certified for quality by ISO and SGS. The minimum order

quantity is 200m, with a price range of 3-5 USD/m. The packaging is

standard sea-worthy packaging, and delivery times are usually

around 15 days. Payment terms are TT, and the supply ability is

5000M/month.

The Jiubei DN200 HDPE pipe is designed for use in a variety of

applications. It is suitable for use in dredging, mining, and other

industries where heavy-duty wear-resistant products are required.

The pipe is available in custom thicknesses, and the connection

methods are fusion welding and steel flanges.

The HDPE pipe is designed to withstand high pressures of up to

2.0Mpa and is available in lengths of 5.8/11.8m per length. It is

also abrasion-resistant, making it ideal for use in environments

where there is a high risk of wear and tear. The DN200 HDPE

pipeline is versatile and can be used in a range of scenarios,

including:

- Dredging operations: The Jiubei HDPE pipe is highly suitable for

use in dredging applications. Its wear-resistant properties make it

ideal for use in harsh environments, where it may be exposed to

abrasive materials.

- Mining: The HDPE pipe is also suitable for use in the mining

industry. It can withstand high pressures and is resistant to

abrasion, making it ideal for use in mining applications.

- Industrial: The Jiubei DN200 HDPE pipeline can be used in a variety

of industrial applications where heavy-duty wear-resistant products

are required. It is a reliable and cost-effective option for

industries that require high-quality products.

The Jiubei DN200 HDPE pipe is a versatile product that is suitable

for use in a range of different scenarios. Its heavy-duty

wear-resistant properties make it ideal for use in harsh

environments, and it is a reliable and cost-effective option for

industries that require high-quality products. If you are looking

for a durable and reliable HDPE pipe, the Jiubei DN200 HDPE

pipeline is an excellent choice.

Support and Services:

The Dredging HDPE Pipe product is supported by a team of technical

experts who are available to provide guidance and assistance

throughout the installation and operation process. Technical

support services include:

- Design and specification assistance

- Installation and commissioning guidance

- Maintenance and repair support

- Performance optimization recommendations

In addition to technical support, the manufacturer also offers a

range of services to ensure the ongoing performance and reliability

of the product:

- Inspection and testing services

- Training and certification programs

- Repair and refurbishment services

- Upgrades and retrofits