High Temperature Cementing Float Gear Designed with Threaded Connection

|

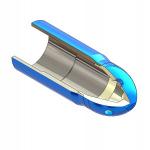

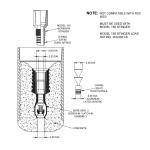

Product Description:Cementing Float Equipment The Cementing Float Equipment is an essential tool used in the oil and gas industry for cementing operations. It is designed to provide a reliable seal between the casing and the wellbore, preventing any fluid from flowing back up the well. Material Made of high-quality steel, the Cementing Float Equipment is durable and able to withstand harsh environments. The use of steel ensures the equipment's strength and longevity, making it a cost-effective solution for cementing operations. Stability With its sturdy steel construction, the Cementing Float Equipment offers high stability during cementing operations. This stability is crucial in ensuring the proper placement of cement and preventing any unwanted movement or displacement. Resistance The Cementing Float Equipment is designed to withstand high pressures and extreme conditions. Its strong resistance to pressure, impact, and wear makes it a reliable choice for cementing operations in challenging environments. Temperature The Cementing Float Equipment is designed to withstand high temperatures that are commonly encountered during cementing operations. Its heat-resistant properties make it suitable for use in both onshore and offshore drilling operations. Corrosion The Cementing Float Equipment boasts low corrosion levels, thanks to its steel construction and protective coatings. This feature ensures the equipment's longevity and reliability, even in corrosive environments. Cementing Float Machinery, Cementing Float Gear, Cementing Float

Apparatus The Cementing Float Equipment is available in various sizes and designs, including Cementing Float Machinery, Cementing Float Gear, and Cementing Float Apparatus. These variations allow for customization and compatibility with different wellbore sizes and cementing operations. In conclusion, the Cementing Float Equipment is a crucial tool for ensuring the success of cementing operations in the oil and gas industry. Its high-quality steel material, stability, resistance, temperature and corrosion resistance make it a reliable and cost-effective choice for any cementing operation. Features:

Technical Parameters:

Applications:Cementing Float Equipment Product Description

Cementing Float Equipment, also known as Cementing Float Instrument, Cementing Float Gear, or Cementing Float Device, is a vital tool used in the oil and gas industry for cementing operations. This product is designed and manufactured by sws, a leading company in China that specializes in high-quality oil and gas equipment. Cementing Float Equipment is used in high-pressure and high-temperature environments, making it highly resistant to extreme conditions. It is available in customized sizes to fit different wellbore sizes and specifications. The use of this equipment ensures a successful and efficient cementing operation, as it helps in preventing fluid migration and maintaining well integrity. The lightweight design of Cementing Float Equipment makes it easy to handle and install, reducing the risk of injuries during the cementing process. It is also designed to withstand harsh drilling conditions, ensuring its durability and longevity. With its high-quality materials and precise engineering, this product has become a popular choice among oil and gas companies worldwide. Customization:Customization Service for Cementing Float Equipment Brand Name: SWS Place of Origin: China Durability: High Performance: Excellent Resistance: High Material: Steel Size: Customized Features of Our Cementing Float Machinery:

Why Choose Our Cementing Float Instrument?

Customization Process for Cementing Float Instrumentation: Step 1: Consultation - Our experienced team will discuss your specific needs and requirements for the cementing float equipment. Step 2: Design - Based on the consultation, we will design a customized solution that meets your specifications and project goals. Step 3: Production - Using high-quality steel material and advanced technology, we will produce the customized cementing float equipment. Step 4: Testing - Before shipment, all equipment will undergo strict testing to ensure high performance and durability. Step 5: Delivery - We will arrange for prompt and reliable delivery of your customized cementing float equipment to your desired location. Choose SWS for your customized cementing float equipment needs and experience high-quality, efficient, and reliable solutions. Contact us today to learn more. Packing and Shipping:Packaging and Shipping for Cementing Float Equipment The Cementing Float Equipment is packaged and shipped in accordance with industry standards to ensure safe and secure transportation. The packaging materials used are chosen to protect the product from any damage during transit. The following are the details of the packaging and shipping process for this product:

Our company works with reliable and experienced shipping partners to ensure timely delivery and safe handling of the Cementing Float Equipment. Any special packaging or shipping requirements can be accommodated upon request. FAQ:

|

||||||||||||||||||||||||

| Product Tags: Offshore Cementing Float Gear High Temperature Cementing Float Gear Customized Steel Cementing Float Apparatus |

|

API 5CT 7 5/8" Single Valve Eccentric Nose Aluminum Alloy Float Shoe With L80 LTC for Casing and Tubing in Oilfield |

|

EU Thread API Standard Aluminum Alloy Guide Shoe |

|

API Standard Cement Guide Shoe For Oil And Gas Industry |

|

API Standard Single Valve Float Collar And Shoe With PDC Valve |

|

API Standard Stab In Float Collar And Shoe With 100% PDC Accessories For Cementing Wells |

|

API Standard Double Valve Float Collar And Shoe For Preventing Backflow |