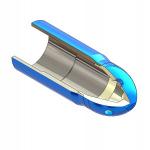

Lightweight Cementing Float Equipment with Threaded Connection for Efficiency

|

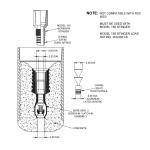

Product Description:Cementing Float Equipment Overview Cementing Float Gear, also known as Cementing Float Device, is an essential tool used in the oil and gas industry for well cementation. It is designed to provide a stable platform for the cementing process and ensure the proper placement of cement in the wellbore. This product overview will highlight the key attributes of Cementing Float Equipment, including its corrosion resistance, reasonable cost, high stability, durability, and resistance. Corrosion Resistance Cementing Float Gear is manufactured using high-quality materials that provide excellent corrosion resistance. This ensures that the equipment can withstand harsh drilling environments and maintain its functionality over an extended period. The materials used in the production of Cementing Float Gear are carefully selected and undergo rigorous testing to ensure they can withstand corrosive elements such as saltwater, acids, and chemicals. Reasonable Cost One of the key advantages of Cementing Float Gear is its reasonable cost. Despite its high-quality materials and advanced design, this product is available at a reasonable price, making it a cost-effective choice for oil and gas companies. This makes it an attractive option for companies looking to reduce their operational costs without compromising on the quality and performance of their equipment. High Stability The design of Cementing Float Gear is focused on providing high stability during the cementing process. The equipment is equipped with multiple buoyancy chambers that provide a stable and balanced platform for the cementing operation. This ensures that the cement is evenly distributed throughout the wellbore, resulting in a more efficient and effective cementation process. Durability Cementing Float Gear is designed to withstand the harsh conditions of drilling operations. It is built to last and can withstand extreme temperatures, pressure, and other environmental factors. This ensures that the equipment can be used repeatedly without compromising its performance or requiring frequent replacements, saving time and money for oil and gas companies. Resistance Another key attribute of Cementing Float Gear is its high resistance to wear and tear. The equipment is designed to withstand the impact of drilling operations, such as debris and abrasive materials, without compromising its functionality. This makes it a reliable and long-lasting choice for oil and gas companies, reducing the need for frequent replacements and repairs. In conclusion, Cementing Float Equipment is an essential tool for well cementation, offering corrosion resistance, reasonable cost, high stability, durability, and resistance. Its advanced design and high-quality materials make it a reliable and cost-effective choice for oil and gas companies. With proper maintenance, Cementing Float Gear can provide long-term performance and contribute to the success of drilling operations. Features:

Technical Parameters:

Applications:Cementing Float Equipment - sws Brand Name: sws The Cementing Float Equipment by sws is an essential tool used in oil well cementing operations. This high-quality, durable equipment is made from steel and has low corrosion, making it perfect for use in harsh environments. The Cementing Float Gear is designed to provide support and stability during cementing operations. It is placed at the bottom of the casing string to prevent cement from flowing back into the casing. This ensures a proper cement seal is formed, preventing any potential leaks or damage to the well. The Cementing Float Apparatus is also equipped with a valve and a float collar, which allows for the release of trapped air and helps to maintain a consistent flow of cement. This ensures a smooth and efficient cementing process. During cementing operations, the Cementing Float Device plays a crucial role in maintaining the integrity of the well. It helps to prevent any potential damage or accidents, ensuring a safe and successful cementing process. With its high resistance and durability, the Cementing Float Equipment by sws can withstand high temperatures and harsh conditions, making it a reliable and long-lasting tool for oil well cementing operations. Overall, the Cementing Float Equipment by sws is a vital component in the oil well cementing process. Its high-quality materials and design make it a trustworthy and efficient tool for any cementing operation. Customization:Cementing Float Equipment Customization Service Brand Name: SWS Place of Origin: China Connection: Threaded Stability: High Pressure: High Resistance: High Corrosion: Low Key Words: Cementing Float Machinery, Cementing Float Device, Cementing Float Gear, Cementing Float System Support and Services:Technical Support and Services for Cementing Float Equipment Thank you for choosing our Cementing Float Equipment. We are dedicated to providing high-quality products and excellent technical support and services to ensure the success of your cementing operations. Technical Support Our team of experienced engineers and technicians are available 24/7 to provide technical support for any issues or concerns you may have with our Cementing Float Equipment. We offer remote assistance, on-site support, and troubleshooting services to help you resolve any problems quickly and efficiently. Training and Consultation We offer training and consultation services to ensure that your team is well-equipped with the knowledge and skills to operate our Cementing Float Equipment effectively. Our training programs cover product operation, maintenance, and troubleshooting, and can be customized to meet your specific needs. Spare Parts and Maintenance We provide a wide range of spare parts for our Cementing Float Equipment to ensure minimal downtime and maximum efficiency. Our maintenance services include regular inspections and preventive maintenance to keep your equipment in top condition. Quality Assurance We adhere to strict quality control measures to ensure that our Cementing Float Equipment meets the highest industry standards. Our products undergo rigorous testing and inspection before leaving our facility to ensure their reliability and durability. Customer Service Our dedicated customer service team is always available to assist you with any inquiries or concerns. We value our customers and strive to provide prompt and efficient service to ensure your satisfaction with our Cementing Float Equipment. Feedback and Improvement We welcome any feedback or suggestions for improvement regarding our Cementing Float Equipment. Your input is valuable to us and helps us continuously enhance our products and services to better meet your needs. Thank you again for choosing our Cementing Float Equipment. We are committed to providing the best technical support and services to help you achieve successful cementing operations. If you have any further questions or require assistance, please do not hesitate to contact us. Packing and Shipping:Packaging and Shipping The Cementing Float Equipment is packaged and shipped in a sturdy wooden crate to ensure safe delivery. The crate is securely sealed and labeled with all necessary shipping information, including product name, quantity, and destination address. For international shipments, the equipment is packaged according to international export standards and may include additional protective measures to withstand long-distance transportation. Upon arrival, the crate is carefully unloaded and inspected for any damages that may have occurred during transit. If any damages are found, please contact our customer service team immediately for assistance. Our company works with trusted shipping partners to ensure timely and efficient delivery of our products to our customers. We offer a variety of shipping options to meet your specific needs and budget. For more information on our packaging and shipping process, please contact us at [insert contact information here]. FAQ:

|

|

API 5CT 7 5/8" Single Valve Eccentric Nose Aluminum Alloy Float Shoe With L80 LTC for Casing and Tubing in Oilfield |

|

EU Thread API Standard Aluminum Alloy Guide Shoe |

|

API Standard Cement Guide Shoe For Oil And Gas Industry |

|

API Standard Single Valve Float Collar And Shoe With PDC Valve |

|

API Standard Stab In Float Collar And Shoe With 100% PDC Accessories For Cementing Wells |

|

API Standard Double Valve Float Collar And Shoe For Preventing Backflow |