Steel Cementing Float Equipment For Durable In Harsh Environments

|

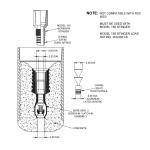

Steel Cementing Float Equipment For Durable In Harsh EnvironmentsProduct Description:Cementing Float Equipment The Cementing Float Equipment is a vital component in the cementing process of oil and gas wells. It is designed to prevent the backflow of cement during the cementing operation, ensuring a successful and efficient well completion. This product overview will provide a detailed description of the Cementing Float Equipment, highlighting its key attributes and benefits. Product Description The Cementing Float Equipment, also known as Cementing Float Gear, Cementing Float Apparatus, or Cementing Float Instrument, is a specialized tool used in the cementing process of oil and gas wells. It is installed at the bottom of the casing string, forming a seal against the wellbore and allowing the cement to flow through it. Key Attributes The Cementing Float Equipment possesses several key attributes that make it an essential tool in the cementing process:

Benefits The Cementing Float Equipment offers several benefits to operators during the cementing process:

Conclusion In conclusion, the Cementing Float Equipment is a crucial tool in the cementing process of oil and gas wells. Its light weight, high pressure and temperature capabilities, high durability, and reasonable cost make it a top choice for operators. With its reliable and effective performance, the Cementing Float Equipment is a valuable investment for any well completion operation. Features:

Technical Parameters:

Key Features:

Applications:Cementing Float Equipment - The Perfect Choice for High

Temperature, High Stability, and High Pressure Cementing

Applications Brand Name: SWS Place of Origin: China Application: Cementing Temperature: High Stability: High Pressure: High Weight: Light When it comes to cementing operations in high temperature, high stability, and high pressure environments, the SWS Cementing Float Equipment is the go-to choice for professionals in the oil and gas industry. From its advanced design to its superior performance, this product is specifically engineered to meet the rigorous demands of cementing applications. What is Cementing Float Equipment? Cementing Float Equipment, also known as Cementing Float Gear or Cementing Float Instrument, is a crucial component in the cementing process for oil and gas wells. It is used to provide a reliable barrier between the cement slurry and the hydrostatic pressure of the wellbore, ensuring proper cement placement and preventing any potential blowouts or other well control issues. Applications The SWS Cementing Float Equipment is primarily used in the oil and gas industry for cementing operations. It is designed to be used in high temperature environments, making it ideal for wells with high geothermal gradients. Its high stability and pressure capabilities also make it suitable for use in deepwater and high-pressure wells. Scene Scenario Imagine a team of engineers preparing for a cementing operation in a high temperature, high stability, and high pressure well. They know that they need a reliable and efficient cementing float apparatus to ensure the success and safety of their operation. After careful consideration, they choose the SWS Cementing Float Equipment. The team quickly assembles the equipment and installs it in the wellbore. The lightweight design of the equipment makes it easy to handle and maneuver, even in harsh and challenging environments. The high temperature and pressure resistance of the equipment give the team confidence that it will perform well under the intense conditions of the well. As the cementing process begins, the team observes how smoothly the equipment operates, and how it effectively seals the annulus, preventing any fluid migration or pressure buildup. With the SWS Cementing Float Equipment in place, the team successfully completes the cementing operation, achieving a strong and reliable wellbore barrier. Conclusion The SWS Cementing Float Equipment is the top choice for professionals in the oil and gas industry when it comes to cementing operations in high temperature, high stability, and high pressure conditions. Its advanced design, superior performance, and lightweight construction make it the ideal product for ensuring the success and safety of cementing operations in challenging environments. Customization:Cementing Float Equipment Customized Service Brand Name: SWS Place of Origin: China Connection: Threaded Size: Customized Material: Steel Performance: Excellent Resistance: High Introducing SWS Cementing Float Equipment SWS is a leading manufacturer of high-quality cementing float machinery, providing customized services for our clients. Originating from China Our cementing float devices are proudly made in China, ensuring the highest quality materials and manufacturing processes. Threaded Connection for Easy Installation Our cementing float machinery equipment is designed with a threaded connection, making it easy to install and secure in place. Customized Size for Your Specific Needs At SWS, we understand that every project is unique. That's why we offer customized sizes to meet the specific requirements of your cementing operations. Durable Steel Material Our cementing float equipment is made of high-quality steel, ensuring durability and longevity even in the harshest environments. Excellent Performance Guaranteed With our advanced manufacturing processes and strict quality control, we guarantee excellent performance from our cementing float machinery. High Resistance to Wear and Tear SWS cementing float equipment is designed to withstand high pressure and harsh conditions, ensuring long-lasting performance and minimal downtime. Customize Your Cementing Float Equipment with SWS Choose SWS for your next cementing project and experience the benefits of our customized services, high-quality products, and excellent performance. Support and Services:Cementing Float Equipment Technical Support and Service Welcome to our technical support and service page for Cementing Float Equipment. Our team of experts is dedicated to providing you with the highest quality products and the best possible service to ensure the success of your cementing operations. Technical Support Our technical support team is available 24/7 to assist you with any questions or concerns you may have regarding our Cementing Float Equipment. We have a thorough understanding of our products and are committed to finding solutions to any technical issues that may arise. We also offer on-site technical assistance for larger projects or complex installations. Our experienced technicians will work closely with your team to ensure that the equipment is installed correctly and functioning properly. Service In addition to providing top-notch products, we also offer a variety of services to support your cementing operations. These include:

Our service team is highly skilled and can handle any maintenance or repair needs for your Cementing Float Equipment. We also offer rental options for short-term projects or when additional equipment is needed. Training is an important aspect of our services, as we want to ensure that your team is knowledgeable and confident in using our products. We offer training sessions on-site or at our facility, tailored to your specific needs. If your project requires specialized equipment, our team can work with you to customize our Cementing Float Equipment to meet your specific requirements. We are committed to providing you with the best possible solutions for your cementing operations. Thank you for choosing our Cementing Float Equipment. Our team is dedicated to providing top-quality products and excellent service to meet all of your cementing needs. Please contact us for any technical support or service inquiries, we are always happy to assist you. Packing and Shipping:Packaging and Shipping of Cementing Float Equipment Our Cementing Float Equipment is carefully packaged to ensure safe delivery to our customers. It is important to us that our products arrive in perfect condition and ready for use. We use high-quality materials and take great care in the packaging process to protect our products during shipping. Packaging Process First, the Cementing Float Equipment is inspected for any defects or damages. It is then cleaned and dried to remove any dirt or debris. Next, it is carefully placed in a sturdy cardboard box and secured with packing materials such as bubble wrap or foam. The box is then sealed with strong tape to prevent any movement during shipping. Shipping Methods We offer various shipping methods to meet the needs of our customers. Our standard shipping option is through a reputable courier service, which provides fast and reliable delivery. For larger orders, we also offer freight shipping to ensure the safe transport of our products. Shipping Documents Along with the Cementing Float Equipment, we provide all necessary shipping documents such as a packing list and commercial invoice. These documents are required for customs clearance and to ensure a smooth delivery process. Custom Packaging We understand that some customers may have specific packaging requirements. We offer custom packaging options to meet these needs. Our team works closely with our customers to create a packaging solution that meets their specifications and ensures the safe delivery of our products. Thank you for choosing our Cementing Float Equipment. We are committed to providing high-quality products and reliable shipping to our valued customers. FAQ:

|

||||||||||||||||||||||

| Product Tags: Steel Cementing Float Equipment Customized Steel Cementing Float Equipment Threaded Casing Float Equipment |

|

API 5CT 7 5/8" Single Valve Eccentric Nose Aluminum Alloy Float Shoe With L80 LTC for Casing and Tubing in Oilfield |

|

EU Thread API Standard Aluminum Alloy Guide Shoe |

|

API Standard Cement Guide Shoe For Oil And Gas Industry |

|

API Standard Single Valve Float Collar And Shoe With PDC Valve |

|

API Standard Stab In Float Collar And Shoe With 100% PDC Accessories For Cementing Wells |

|

API Standard Double Valve Float Collar And Shoe For Preventing Backflow |