Hard Bearing Double Sided Vertical Balancing Machine ISO2953-85 GB/T4201-2006

|

|

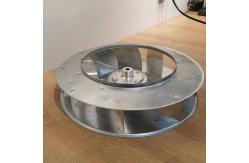

Hard Bearing Double-sided Vertical Balancing Machine The HZ-L16 series product is a kind of HZ series vertical structure hard support balancing machine with a wide range of uses, which is designed and manufactured by our factory by introducing foreign advanced technology. It is widely used in water pump impellers, brake discs, saw blades, fans, Balance test of disc workpieces such as pulleys and tires. The display part of this product is a 10.4-inch LCD touch screen display. It not only has the characteristics of large measurement range, high efficiency, safe and simple operation, and intuitive display, but also occupies a leading position in the domestic balancing machine industry. . Precautions Installation of the balancing machine 1. The compressive strength of the foundation concrete is ≥16MP,

the foundation uses No. 525 cement, and the secondary grouting uses

No. 625 cement. 2. The installation level of the machine is ≤0.2/1000. The machine

needs to be grouted twice after the level adjustment. The grouting

should be fully padded, and the anchor bolts should be tightened

after the foundation is completely dry. Industrial control measurement system The measurement system is the core of the balancing machine. This

system uses the latest CPU computing chip, after signal

amplification, filtering, analog-to-digital conversion, and then

computing to display the measurement data. At the same time, it

also has the output of database, communication data and control

signal, including the connection of printer. Man-machine dialogue

interface, intuitive and easy to operate, suitable for display in

industrial production environments. After rigorous multi-level

component screening, large-scale electrical circuit manufacturing

technology, coupled with high and low temperature aging tests, it

is suitable for balancing machines to perform accurate measurements

in different environments. Quality Standard 1. accordance with GB/T4201-2006 standards. 2. Quality assurance period: Within 12 months from the completion

of commissioning, the product will be maintained for life. 3. Acceptance criteria: Before leaving the factory, the supplier

shall check and accept the balancing machine according to the

ISO2953-85 standard, and issue a certificate of conformity. 4. Carry out actual operation and on-site acceptance of the

physical workpiece at the buyer's place, and complete the training

of operators. After-sales service: 1. After the balancing machine arrives at the buyer's site, the

supplier is responsible for the on-site debugging, operation

training and common troubleshooting training of the balancing

machine. 2. If the equipment fails, our company will respond and

support within 48 hours after receiving the buyer's notice. 3. The

equipment is free of charge during the "three guarantees", and

after the "three guarantees", life-long maintenance services and

parts replacement services Specification |

| Product Tags: 800r/min Vertical Balancing Machine Hard Bearing Vertical Balancing Machine Vertical Dynamic Balancing Machine |

|

Rotor Belt Drive Dynamic Balancing Machine Manufacturer 1~20 KG 400-3000 R/Min Balance Speed |

|

1/2/3 Plane Balancing Machine System 120W With 0-6000rpm Rotation Speed |

|

220V LED Display Dynamic Balancing Machine 6000rpm For High Precision |

|

ISO 21940 Dynamic Balancing Machine For Grinding Plate Rotor Unbalance Correction 2000MM |

|

120 N.M Dynamic Balancing Machine Of Drive Shaft Torque 1000kg Of ISO 21940 Test |

|

Grinding Wheel Motor Dynamic Balancing Machine Rotor Pump 120-5000 R/Min 1000KN |