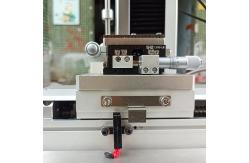

IEC 60068-2-21-2006 500N Inductance Thrust Test Equipment Hz-1007D Fully Automatic Thrust Testing Machine1007D series automatic thrust testing machine is a new type of

material testing machine combining electronic technology and

mechanical transmission. It has a wide and accurate loading speed

and force measurement range, and has high precision and sensitivity

for the measurement and control of load, deformation and

displacement. This series of models adopts a single-space

structure, and the test space is in the lower space. It is mainly

suitable for the test of metal and non-metal materials with a test

load of less than 500N (50KG). It has stress, strain, and

displacement control methods, and can test the maximum thrust,

compressive strength, Bending strength and other test requirements. Meet the standard GB/T 16491-2008 electronic universal testing machine, and also meet

ASTM D412, ASTM D638, GB/T 1040,GB/T 8808, GB/T 13022, GB/T 2790,

GB/T 2791, GB/T 2792, GB/T 16825, GB/T 17200,GB/T 3923.1, GB/T2611,

GB/T 6344, GB/T 20310, GB/T 3690, GB/T 4944, GB/T 3686,GB/T 6344,

GB/T 10654, GB/T 2423.60 (IEC 60068-2-21-2006) and many other

domestic and international testing standards. Model Number | HZ-1007D | Pressure value | 10N, 50N, 100N, 200N, 500N (other capacities can be customized) | Accuracy class | Level 0.5 | Force range | 0.4%~100% | Force measurement accuracy | Within ±0.5% of indicated value | Resolution | maximum load is 1/200000 | sensor | Basic configuration: a pressure sensor (maximum load) | SERVICR | OEM ODM | warranty | 1 year | Test speed range | 0.1~200mm/min (speed can be customized) |

Main FeatureImported photoelectric encoder is used for displacement

measurement, the controller adopts embedded single-chip

microcomputer structure, built-in powerful measurement and control

software, which integrates measurement, control, calculation and

storage functions. It has the function of automatically calculating

stress, tensile strength and elastic modulus, and automatically

counts the results; automatically records the maximum point,

breaking point, force value or elongation of the designated point;

uses the computer to display the dynamic display of the test

process and test curve, and Perform data processing. After the

test, the graph processing module can be used to zoom in on the

curve for data reanalysis and editing, and can print reports. The

product performance has reached the international advanced level. FunctionIt is mainly suitable for testing metal and non-metal materials,

such as springs, inductors, electronic product keys, touch screen

pressure, sponges, foams, conforming materials and other

compression, bending and other samples. This fully automatic thrust

testing machine can realize 1 -The automatic test in 16 stations

can also be adjusted according to the actual needs of customers,

set up the program, and automatically push the product to display

the thrust data Software testing main interface 1.Sample parameters can be set, fixed speed, positioning

displacement, fixed force and other tests can be set2.Change the content displayed on the left side of the software,

and select the maximum force, deformation, displacement, etc. 3.Editable test criteria and test requirements Other test items 1. Thrust test Set the fixture distance program to set the

automatic thrust test.2. Stress test Set the force value to see the deformation is the

data 3. The coefficient of elasticity is the Young's modulus of

elasticity Definition: The ratio of the normal stress component in

phase to the normal strain. It is a coefficient for determining the

rigidity of a material. The higher the value, the stronger the

material. 4. Proportional limit: The load can maintain a proportional

relationship within a certain range, and its maximum stress is the

proportional limit. 5. Elastic limit: the maximum stress that a material can withstand

without permanent deformation. 6. Elastic deformation: After removing the load, the deformation of

the material disappears completely. 7. Permanent deformation: After removing the load, the material

still remains deformed. 8. Fully automatic test: multiple stations can be selected for

automatic testing Precautions In a non-emergency state, please try to avoid directly turning off

the power supply in the running state; Non-electrical maintenance

personnel, please do not open the back door of the control cabinet

to avoid possible personal injury to you; When inputting

parameters, please check the correctness of parameter input; Before

the test, please review the installation status of the mechanical

part again to confirm that each connecting screw is in place |