Product Description:

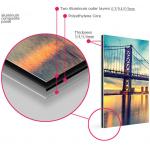

Polyvinylidene Fluoride (PVDF) Aluminium Composite Panel is a

fluorine-based aluminium composite panel which is widely used in

building and decoration. It has superior characteristics such as

impact strength, surface treatment, fireproof grade, elongation and

core material. The impact strength of PVDF aluminium composite

panel is up to more than 3KJ/m2. It is available in PE coated or

PVDF coated options for different surface treatments. It is also

fireproof grade B1 and A2 certified. Moreover, it has a high

elongation of more than 25%. Overall, PVDF Aluminum Composite Panel

is known for its excellent performance and reliability with a core

material of PE, FR and Mineral.

Features:

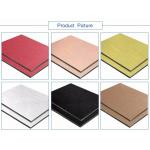

- Product Name: PVDF Aluminum Composite Panel

- Surface Treatment: PE Coated, PVDF Coated

- Color: White, Black, Red, Blue, Green, Yellow, Etc.

- Core Material: PE, FR, Mineral

- Impact Strength: ≥3KJ/m2

- Brand: Megabond

- Polyvinylidene Fluoride Aluminum Panel: Yes

- Vinylidene Fluoride Aluminium Panel: Yes

- Vinylidene Fluoride Composite Panel: Yes

- Polyvinylidene Fluoride Composite Panel: Yes

Technical Parameters:

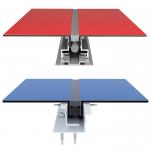

| Property | Value |

|---|

| Material | PVDF Aluminum Composite Panel |

| Formaldehyde Emission | E1, E2 |

| Thickness | 3mm, 4mm, 5mm, 6mm |

| Color | White, Black, Red, Blue, Green, Yellow, Etc. |

| Surface Hardness | ≥HB |

| Surface Treatment | PE Coated, PVDF Coated |

| Tensile Strength | ≥24MPa |

| Impact Strength | ≥3KJ/m2 |

| Bending Strength | ≥100MPa |

| Elongation | ≥25% |

| Fluorine-Based Aluminium Composite Panel | Vinylidene Fluoride Aluminium Panel, Fluorine-Based Aluminum

Composite Panel |

Applications:

PVDF Aluminum Composite Panel, also known as Fluorine-Based

Aluminium Composite Panel, is a kind of Fluorine-Based Aluminum

Composite Panel with the brand name of megabond and model number of

megabond007. It is manufactured in China and certified by SGS and

ISO. The minimum order quantity of the panels depends on the

thickness of the aluminum. It is packaged in wooden crates and

usually takes 15-20 days for delivery. The payment terms include

visa, mastercard, T/T and PAYPAL. The supply ability of the product

is 12000 square meters per day. The core material of the panel is

PE, FR, or Mineral. The thickness of the panel is 3mm, 4mm, 5mm and

6mm. The width of the panel is 1220mm, 1250mm, 1500mm and 1550mm.

The tensile strength of the panel is ≥24MPa and its fireproof grade

is B1 or A2.

Customization:

We offer customized Polyvinylidene Fluoride Aluminum Panel, Polyvinylidene Fluoride Composite Panel, Vinylidene Fluoride Composite Panel at Megabond. Our product model number is megabond007 and is certified by SGS and ISO. The minimum order quantity depends on the aluminum thickness, and

the packaging details are wooden crates. The delivery time is 15-20

days, and the payment terms are visa, mastercard, T/T, and PAYPAL.

We have a supply ability of 12000 square meters per day. Our

formaldehyde emission meets E1 or E2 standards. The thickness

available are 3mm, 4mm, 5mm, and 6mm. The core material is PE, FR,

or mineral. The impact strength is ≥3KJ/m2 and surface hardness is

≥HB.

Support and Services:

Technical Support and Service for PVDF Aluminum Composite Panel

At ABC company, we strive to provide our customers with the best

technical support and service. Our team of experienced

professionals are available to answer any questions you may have

about our PVDF Aluminum Composite Panel products.

We understand that installing a new product can be a daunting task,

which is why we offer a range of resources to help you along the

way. Our customer service team is available to provide step-by-step

guidance through installation, and we also provide detailed product

documentation on our website.

We are committed to providing top-notch technical support and

service for our PVDF Aluminum Composite Panel products. If you ever

have any questions or concerns, please don’t hesitate to reach out

to us.

Packing and Shipping:

Packaging and Shipping for PVDF Aluminum Composite Panel:

The PVDF Aluminum Composite Panel is packaged and shipped in

protective cases. Each panel is securely fastened to a pallet with

shrink wrap and/or strapping. The cases are then placed in a

cardboard box for additional protection during shipping. The box is

sealed with tape to ensure that it stays intact during transit. The

products are then shipped via ground, sea, or air freight depending

on the customer's preference.

FAQ:

- Q: What is PVDF Aluminum Composite Panel?

- A: PVDF Aluminum Composite Panel is a composite material made of

aluminum and polyvinylidene fluoride (PVDF). The surface of the

panel is coated with PVDF fluorocarbon coating which has excellent

weather resistance, corrosion resistance, and color retention.

- Q: What is the Brand Name of PVDF Aluminum Composite Panel?

- A: The Brand Name of PVDF Aluminum Composite Panel is megabond.

- Q: What is the Model Number of PVDF Aluminum Composite Panel?

- A: The Model Number of PVDF Aluminum Composite Panel is

megabond007.

- Q: Where is the Place of Origin of PVDF Aluminum Composite Panel?

- A: The Place of Origin of PVDF Aluminum Composite Panel is China.

- Q: What Certifications does PVDF Aluminum Composite Panel have?

- A: PVDF Aluminum Composite Panel has SGS and ISO Certifications.