Shockproof Composite 4x8 Sheets Panel Anticorrosive Multipurpose

|

|

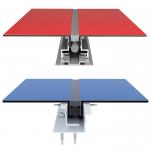

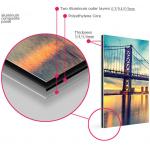

PVDF Aluminum Composite Panel Lemari Acp Boards Bracket Router 4x8 Fluorocarbon aluminum composite panel is made of a mixture of fluorocarbon resin with fluorine enzyme as the basic monomer, paint, alcohol ester solvent and accessory ingredients. The molecular structure in the coating is compact after being high -temperature baked into film formation, which provides the composite panel with extra-strong weather resistance. The fluorocarbon coating falls into conventional fluorocarbon coating. Conventional fluorocarbon is made of KYNAR500 fluorocarbon and is solidified into film formation on the surface after three coats and three bake. The superior quality coating provides the aluminum composite panel with good acid and alkali resistance, and allows the panel to stand the test of severe environment. So, PVDF coated ACP has no abnormal depigment within 15 to 20 years, which is more applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

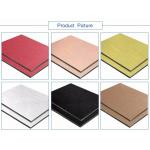

The features of PVDF aluminum composite panel are immense simply because of the fact that they make the surface of the panel even more flat. The coating gives the two aluminum sheets a surface whose essential feature is flatness and smoothness. Furthermore, the PVDF coating makes it even more weather resistant. Also features such as heat insulation, sound insulation and fire resistant add an entirely new dimension in Aluminum composite panels. The usage of PVDF aluminum composite panel is wide and has a variety of applications; it is frequently used as a raw material in industries, advertisement boards and exterior of buildings.

PVDF ACP, also known as Polyvinylidene Fluoride coating composite panels, makes for excellent building materials. PVDF composite panels are of durable make and demonstrate sturdiness that is fit for outdoor applications due to their thermal resistance and durability. Make use of their resiliency and versatility in your next project!

PVDF aluminum composite panels are extensively used for the purpose

of cladding, as we have seen that their thickness along with the

properties of PVDF are such that they are perfect material for

cladding.

Feature ·Weather Resistance & High Strength ·Easy Maintenance & Excellent Processability ·Convenient for Project Construction ·Thermal Resistance & Sound Insulation ·Good Fire Prevention Performance ·Good Plasticity & Impact Resistance ·Shock Resistance & Good Smoothness ·Light, Strong & Choosing Color ·Gorgeous & Colorful Decorative ·Decorative Pattern & Design Can Be Customized

|

||||||||||||||||||||

| Product Tags: Shockproof Composite 4x8 Sheets Anticorrosive Composite 4x8 Sheets Multipurpose Composite Panel Sheet | ||||||||||||||||||||

|

PVDF Coated Aluminum Composite Panel with FR Core for Building Decoration |

|

Customizable Signage Board Aluminum Plastic Composite Panels PE PVDF Color Building And Decoration Material |

|

Customizable Aluminum Composite Panel Recyclable UV Aging Resistant Anti Corrosion ACP Sheet |

|

B1 Fireproof Grade FR Core Polyvinylidene Fluoride Composite Panel With Surface Hardness ≥HB |

|

Black Polyvinylidene Fluoride Aluminium Panel A2 Fireproof Grade |

|

4mm Fluorine Based Aluminum Panel E1 Formaldehyde Emission PE Core Material |