Product Description:

Rotomoulding Mould is a customized mold with wall thickness of

8-10mm, made of aluminum alloy. It is used mainly for rotational

moulding, with a warranty of 1 year. Its weight can be customized

according to customers' needs. With its strong construction and

reliable performance, Rotomoulding Mould is an ideal choice for

rotational moulding. It is also corrosion-resistant and highly

durable, offering years of reliable service.

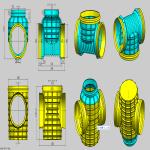

Applications:

Rotomoulding Mould is designed for various applications, such as

storage tanks, plastic parts, plastic containers, and other

products. The product is highly customizable, with designs and

colors that can be tailored to the customer's specific needs. The

product features a silver color, and is subject to annealing, which

helps ensure its structural integrity and durability. The product

also features a tolerance of ±0.1mm, ensuring a smooth surface free

from defects. The high quality of the surface allows for excellent

performance in a variety of applications, making it the perfect

choice for any rotational molding project.

Customization:

Rotomoulding Mould Customization Service

Our Rotomoulding Mould customization service is designed to meet

your individual requirements. We provide a variety of options,

including application, weight, thickness, package, and design. Here

are the details:

- Application: Rotomoulding

- Weight: Customized

- Thickness: 3mm

- Package: Wooden Case

- Design: Customized

We are committed to providing top-quality Rotomoulding Moulds that

meet your exact specifications and requirements. Contact us today

to discuss your Rotomoulding Molding needs.

Support and Services:

Rotomoulding Mould Technical Support and Service

- Provide product information and technical consultation

- Provide product installation, commissioning, maintenance and repair

services

- Provide technical training and other related services

- Provide technical support for product application

- Provide quality assurance services

- Provide emergency response services

- Provide software upgrade services

- Provide remote technical services

Packing and Shipping:

Rotomoulding moulds should be packaged and shipped in a way that

prevents damage to the moulds during transit. This includes using

proper packaging materials such as bubble wrap, foam, cardboard,

and plastic wrap. The moulds should also be secured within the

packaging to ensure that they do not move or shift during transit.

The moulds should also be labelled with a shipping label that

clearly states the sender and receiver's contact information as

well as the weight and dimensions of the package.

In addition, the moulds should be shipped via a reliable courier

service with insurance to ensure safe delivery. The courier should

provide proof of delivery and tracking information to ensure that

the moulds are delivered safely and on time. Finally, the moulds

should be inspected upon receipt to ensure that they were received

in good condition.

FAQ:

- Q: What is Rotomoulding Mould?

- A: Rotomoulding Mould is a kind of moulding technique that produces

hollow parts and components with complex shapes and sizes.

- Q: What materials can be used for Rotomoulding Mould?

- A: Rotomoulding Mould can be made from a variety of materials,

including polymers plastics, metals, and even ceramics.

- Q: What are the benefits of using Rotomoulding Mould?

- A: Rotomoulding Mould offers a number of advantages, including cost

savings, the ability to produce complex shapes, a high degree of

flexibility, and durability.

- Q: What is the lead time for Rotomoulding Mould?

- A: The lead time for Rotomoulding Mould depends on the complexity of

the design and the material used, but typically ranges from 4 to 6

weeks.

- Q: What is the cost of Rotomoulding Mould?

- A: The cost of Rotomoulding Mould is dependent on the complexity of

the design, the material used, and the size of the mould. Generally

speaking, the cost is relatively low compared to other moulding

processes.