Product Description:

Rotomoulding Mould is a kind of mould specially designed for

rotomoulding. It has been heat treated by annealing, which improves

its strength and hardness, making it suitable for more demanding

applications. It can be customized in terms of size and design to

meet the specific requirements of the customer, and its tolerance

can be as low as ±0.1mm. With its excellent performance and high

precision, Rotomoulding Mould is an ideal choice for rotational

molding and rotational moulding.

Applications:

Rotomoulding Mold is a type of industrial molding that is used to

form plastic products. It is usually made of aluminum alloy and has

a vertical or horizontal shape with a silver color. It is used in

rotomoulding, which is a process that involves heating and cooling

of the mold to create the desired shape. The mold is usually

packaged in a wooden case for better protection during shipment.

This type of molding has many advantages, such as a high degree of

accuracy, low cost, and fast production. It is suitable for

producing a wide range of products, from toys to large industrial

components. Rotomoulding Molds are widely used in the automotive,

medical, and aerospace industries, as they offer precision and

durability. The process is also environmentally friendly, as it

does not require the use of harsh chemicals or solvents.

Customization:

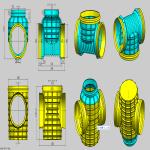

Rotomoulding Mould Customization Service

- Processing: CNC Machining

- Package: Wooden Case

- Weight: Customized

- Tolerance: ±0.1mm

- Material: Aluminum Alloy

- Specializing in Rotational Mold Molding

Support and Services:

Rotomolding Mould provides technical support and services to ensure

the quality of rotomoulding moulds. Through professional technical

support and services, customers can take full advantage of the

rotomolding moulds, create high-quality products and improve

production efficiency.

Our technical support and services include:

- Providing professional advice on the selection of rotomoulding

moulds

- Providing timely repair and replacement services for damaged

rotomoulding moulds

- Providing maintenance services to ensure the normal operation of

rotomoulding moulds

- Providing technical training services to improve the use of

rotomoulding moulds

- Providing customized rotomoulding moulds according to customer

needs

Packing and Shipping:

Packaging and Shipping of Rotomoulding Mould:

Rotomoulding moulds are packaged in wooden crates and securely

strapped for safe transportation. The crates must be inspected for

any damage before being shipped. The moulds also need to be stored

in a dry and protected atmosphere, preferably in an air-conditioned

environment.

Before shipping, the moulds are inspected for any damages and

verified for accuracy. The moulds are then securely strapped and

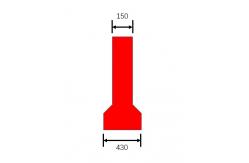

placed in the appropriate sized wooden crate. The dimensions of the

crate will depend on the size of the moulds. The moulds are then

shipped to the destination via a reliable shipping service.

FAQ:

- Q: What is Rotomoulding Mould?

- A: Rotomoulding Mould is a type of mould used in rotomolding for

manufacturing plastic products.

- Q: What are the advantages of Rotomoulding Mould?

- A: The advantages of Rotomoulding Mould include low cost, high

production rate, high flexibility in design, and excellent product

quality.

- Q: What kind of materials can be used with Rotomoulding Mould?

- A: Rotomoulding Mould is suitable for a wide range of materials

including low-density polyethylene (LDPE), high-density

polyethylene (HDPE), polypropylene (PP), polyvinyl chloride (PVC),

polystyrene (PS), and Acrylonitrile Butadiene Styrene (ABS).

- Q: How long does it take to produce a Rotomoulding Mould?

- A: It usually takes about 2-4 weeks to produce a Rotomoulding Mould

depending on the complexity of the design.

- Q: What is the life span of Rotomoulding Mould?

- A: The life span of Rotomoulding Mould depends on the material used

and other factors such as usage, maintenance, and storage

conditions. Generally, the life span can range from several hundred

to several thousand cycles.