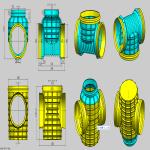

Plastic Rotomoulding Mold For Marine Floater Floating Pontoo Dredge Floating Pipe

|

Detailed Product Description

|

Plastic Rotomoulding Mold For Marine Floater Floating Pontoo Dredge Floating Pipe

How does the rotomoulding process work? Rotomoulding is a relatively simple plastic moulding technique that

uses a hollow mould, usually made from aluminium or stainless

steel. Plastic, usually in powder form, is placed into the mould

which is closed, then rotated on two axes. While it rotates, the mould is heated to a very high temperature,

gradually melting the plastic inside. As it continues to rotate,

the plastic layers up on the inside of the mould. Once all the

plastic has melted, the mould is moved to a cooling station, where

its temperature is reduced using jets of air and, sometimes, a fine

mist of water. The plastic inside solidifies, creating a solid,

hollow shape. Once the now-solid plastic item has cooled down enough, it is

released from the mould and left to cool completely.

Our Certifications

|

||||||||||||||||||||||||||||||||||

| Product Tags: Plastic Rotomoulding Mold Floating Plastic Rotomoulding Mold Dredge Floating Pipe Rotomoulding Mould |

Related Products

|

Die Casting Process Rotomoulding Mould For 5000L Septic Tank Mold Steel Water Tanks |

|

1000L Septic Tank Mold Steel Plastic Mould Custom Processing Service Including Cutting |

|

Boat Mold Kayak Rotational Molding Customizable Durable Rotomoulding Mould For Plastic Manufacturing |

|

1000L Professional Rotomoulding Mould For Septic Tank Mold |

|

Professional Rotomoulding Mould For Water Tank Manufacturing |

|

Customize Rotomolded Plastic Septic Tank Rotomolding Mold |

Email to this supplier