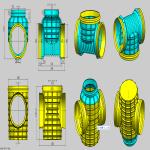

Ground Washing Machine Rotomoulding Mold Custom Rotational Molding Process

|

Detailed Product Description

|

Ground Washing Machine Rotomoulding Mold Custom Rotational Molding Process

The Rotational Moulding Process The rotomoulding process usually involves placing versatile and

readily available polyethylene granules into hollow moulds which

are closed, slowly rotated on two axes, and heated in an oven. This

melts the polymer, after which the mould is moved to a cooling

station wherein the plastic solidifies and, once cooled, is

released away from the moulded surface. Our rotational moulding

process is conceptually simple and more cost-effective compared to

other plastic manufacturing processes, but can be complicated to

carry out. This is because no pressure is involved, which means the

material cannot be controlled as easily as in other high pressure

processes. Variables such as ambient temperature, humidity and

mould type can affect production and the end result. Fortunately,

our team has considerable experience with custom rotational molding

and can help you achieve the best results for your application.

Our Certifications

|

||||||||||||||||||||||||||||||||||

| Product Tags: Ground Washing Machine Rotomoulding Mold Custom Rotational Molding Process |

Related Products

|

Die Casting Process Rotomoulding Mould For 5000L Septic Tank Mold Steel Water Tanks |

|

1000L Septic Tank Mold Steel Plastic Mould Custom Processing Service Including Cutting |

|

Boat Mold Kayak Rotational Molding Customizable Durable Rotomoulding Mould For Plastic Manufacturing |

|

1000L Professional Rotomoulding Mould For Septic Tank Mold |

|

Professional Rotomoulding Mould For Water Tank Manufacturing |

|

Customize Rotomolded Plastic Septic Tank Rotomolding Mold |

Email to this supplier