Rubbish Bin Rotomoulding Mold Process 10000 Cycles

|

Detailed Product Description

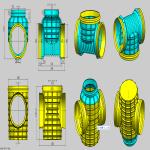

Rubbish Bin Rotomoulding Mold Process 10000 Cycles

Rotational Moulding Mould

Rotational moulding process is a very simple process for

manufacturing hollow, seamless products of all sizes and shapes.

Due to its simple operation and relatively low cost moulds, this

process has become very popular for manufacturing hollow items like

water storage tanks. Rotational moulding is a Four- Stage process. Stage 1 Polymer powder is loaded in the mould manually and mould is closed. Stage 2 The mould is then shifted to the heating oven. Here the mould is

heated by forced hot air circulation. While the mould is heated it

is also rotate about two perpendicular axes simultaneously. The

polymer melts and forms a homogenous layer inside the mould. Stage 3 The mould is shifted to a cooling station where forced air cools

the mould. Stage 4 The mould is open and finished part is taken out. Unlike injection

and blow moulding, rotational moulding does not involve high

pressures, hence the products are stress free and have uniform wall

thickness. Accurate control of process is very important for

producing quality products in rotational moulding.

Our Certifications

|

||||||||||||||||||||||||||||||||||

| Product Tags: Rubbish Bin Rotomoulding Mold Process Rotomoulding Mold 10000 Cycles |

Related Products

|

Die Casting Process Rotomoulding Mould For 5000L Septic Tank Mold Steel Water Tanks |

|

1000L Septic Tank Mold Steel Plastic Mould Custom Processing Service Including Cutting |

|

Boat Mold Kayak Rotational Molding Customizable Durable Rotomoulding Mould For Plastic Manufacturing |

|

1000L Professional Rotomoulding Mould For Septic Tank Mold |

|

Professional Rotomoulding Mould For Water Tank Manufacturing |

|

Customize Rotomolded Plastic Septic Tank Rotomolding Mold |

Email to this supplier