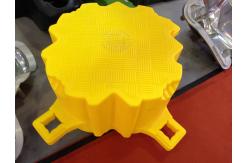

Floating Duck Aluminium Mould Casting Process

|

|

Floating duck aluminium casting mould customerized We make steel and aluminum moulds used for manufacturing polyethylene products. The mould are designed in accordance with the sufficient strength of the product and ergonomics,with the use of specialized 3D software. Our process of developing a mould is very precise at every stage;it is based on the use of profiling,CNC milling and laser cutting techniques. In order to provide the highest quality of rotomoulds,any welding and metalwork are carried out with high accuracy,under ongoing supervision of the team of qualified engineers. The internal surface of steel and aluminum moulds can be,depending on the client’s needs,polished sandblasted or coated.The moulds can be equipped with a logo,a date stamp or markers.

Specification

Wuxi Yisong is special for aluminium casting mould producing we have long year epxerience for design and produce aluminium casting mould

we also have different ball shooting room for many kind of mould surface treatment

We can make your mould more precise and convenience also we can make your mould more smart for loading and demoulding.

Choice us to make the aluminium casting mould, will be your first step toward to win win result. |

||||||||||||||||||||||||||||||||||||

| Product Tags: Floating Duck Aluminium Mould Casting aluminium casting mold process Aluminium rota mold |

|

Family Friendly Aluminum Rotational Molding with Hollow Padding |

|

Aluminum Rotational Molds Suitable For Family Bowl Sinks Type Condition Family |

|

8mm To 10mm Wall Thickness Aluminum Rotational Molding for 1 Seat Customization |

|

Family Aluminum Rotational Molds With 10000 Shots Life And 1 Seat |

|

Home Appliances Aluminum Rotational Molding with Mould Life 10000 Shots |

|

1 Seat Aluminum Rotational Molds with and 10000 Shots Mould Life Polish/Sandblast |