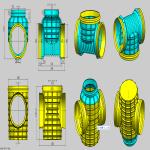

Rotational Moulding Mould For Sewage Inspection Manhole

|

Detailed Product Description

|

Rotational Moulding Mould for Sewage Inspection Manhole

Why rotomolding? 1.Rotational molding, including capital equipment (machinery,

processing equipment, etc.) is a cost effective option for plastic

manufacturing. 2. Rotationally molded parts are 100% stress-free, have excellent

impact resistance, and can withstand chemical and environmental

attack. 3.Value added features, such as threaded tank necks, inserts,

double walls, intricate contours, etc. can be produced via

rotomolding. 4. Speed-to-market advantage: once a design is finalized, tooling

can be produced in a manner of weeks, offering a distinct advantage

over other processes. 5. Rotational molding allows for the integration of multiple parts

into one piece, saving on manufacturing and assembly costs. 6. Large products can be rotationally molded for significantly less

cost as compared to other structural plastics processes. 7. Many tooling options are available and are relatively low in

cost.

Our Certifications

|

||||||||||||||||||||||||||||||||||||

| Product Tags: Rotational Moulding Manhole Mould Sewage Inspection Manhole Mould |

Related Products

|

Die Casting Process Rotomoulding Mould For 5000L Septic Tank Mold Steel Water Tanks |

|

1000L Septic Tank Mold Steel Plastic Mould Custom Processing Service Including Cutting |

|

Boat Mold Kayak Rotational Molding Customizable Durable Rotomoulding Mould For Plastic Manufacturing |

|

1000L Professional Rotomoulding Mould For Septic Tank Mold |

|

Professional Rotomoulding Mould For Water Tank Manufacturing |

|

Customize Rotomolded Plastic Septic Tank Rotomolding Mold |

Email to this supplier