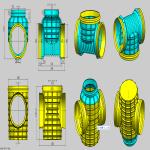

Rotational Moulding Mould | Name | Rotational Moulding Mould | | Shaping Mode | Rotomolding Mould(Rotational Moulding Mould

) | | Surface Treatment | Polishing,Slot Blasting | | Wall Thickness | 8-10mm | | Capacity | 100-5000 L Customised | | Material | Sheet Metal, Mild Steel | | Uselife | 10000 Cycles | | Mold Process | Plasma Cutting + Handwork | | Shape | Vertical / Horizontal | | Feature | With Lid,Water Inlet,Outlet,Valve | | Plastic Product Material | Lldpe, Mdpe, Hdpe, Cross Linked Pe | | Certifications | Iso 9001 ,Arma 2019 2020,2021,2022 | | Color | Customized | | Our Service | Help You Design With Our Professional Experience For Rotational

Mold | | Oem / Odm | Yes | | Mould Life | 1 Year | | Mould Production Cycles | 15-60 Days |

Rotational molding involves a heated mold which is filled with a

charge or shot weight of material. It is then slowly rotated

(usually around two perpendicular axes), causing the softened

material to disperse and stick to the walls of the mold forming a

hollow part. In order to form an even thickness throughout the

part, the mold rotates at all times during the heating phase, and

then continues to rotate during the cooling phase to avoid sagging

or deformation. The process was applied to plastics in the 1950s

but in the early years was little used because it was a slow

process restricted to a small number of plastics. Over time,

improvements in process control and developments with plastic

powders have resulted in increased use. Rotocasting (also known as rotacasting), by comparison, uses

self-curing or UV-curable resins (as opposed to thermoplastics) in

an unheated mould, but shares slow rotational speeds in common with

rotational molding. This kind of rotocasting should not be confused

with centrifugal casting.

Our Certifications

CE Certification of Rotational Mold

CE Certification of Rotational Molding Machine

Member of the Association of Rotational Moulders Australasia 2019

2020,2021,2022

ISO 9001 Quality Management System Certificate

Rotomoulding Professional Committee of ChinaPlastics Processing

Industry Association

12 Patent/Utility Model Patents

Q:Whats your companys' main products?

A:Our company is specialized in the rotationalmolding machines,

moulds,technology R&D .

|

Q:How to control the products quality ?

A:We have always placed great emphasis onquality control to ensure

that excellent qualitylevel is maintained . Moreover , the

principle wealways maintain is " strictly qualitycontrol ,

incessant technology development , highefficiency management system

, and satisfactoryservice .We have CE certification ISO9001 andVB

Certification . ect certificates.

|

Q:How to chose a rotomolding machine of suitable model and size?

A:Yi Song's experience will help you to select the suitable

rotomolding machine!We will do our best to analyze the product

size, output requirements, product characteristics, difficulty of

demolding, mold placement on machine...etc, to recommend a suitable

size and type machine. The more information provided, the more

questions will be settled, and the more suitable machine are be

recommended.

|

Q:What types rotomolding machines do you manufacture?

A:It is fast and easy to start once you can send your product drawing

or picture with size or sample to us!What is more, Rising Sun will

do more works to help you get the perfect product, such

as:a.Product material, structure,

application,thickness,inserts;b.Mould material, locking system,

hoist safety,machine placement, demoulding efficiency;c.Sample

test.All above is respect to customer's initial design or work

under confirmed modification, a professional manager to follow up

from start to final accept.

|

Q:We are plan to make a new mould, what we do to start?

A:Yi Songhas achieved mass production of a variety of equipment: a.

Classification according to production mode: Carrousel rotomolding

machine, shuttle rotomolding machine, rock n roll rotomolding

machine, lined shuttle rotomoldng machine, Single arm rotomolding

machine...b. Classification according to heating mode:Pure hot air,

open flame, Oven electric heating, mould electric heating.c. It's

worth mentioning that it is very cost-effective to customize your

own unique rotomolding equipment in Yi Song.

|

|