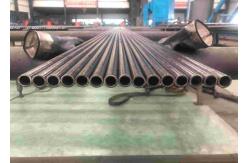

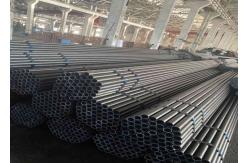

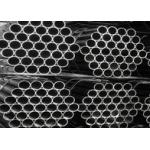

Customized ASTM A179 & ASTM A192 Cold Drawn Seamless Carbon Steel Tube

|

|

Cold Drawn Seamless Tube

1. Definition A cold-drawn seamless tube is a cylindrical product that is manufactured by drawing a solid metal billet through a piercing rod to create a hollow tube without any seams or welds. This seamless construction sets them apart from other types of tubes, such as welded or hot-rolled tubes. The absence of seams enhances the tube’s structural integrity and resistance to various stresses, making it an ideal choice for critical applications.

2. Dimension

3. Production Process Billet Preparation→Heating→Piercing→Elongation→Cold Drawing→Heat Treatment (Optional)→Surface Treatment

4. Application

5. Material, Standard, Grade and Corresponding Characteristics

6. Packaging & Delivery

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ASTM A106 Gr B Pipe High Pressure Boiler Steel Tube Boiler Steel Tube ST44 |

|

Experience Superior Heat Transfer with Heat Exchanger Steel Tube and Durable Solution Available |

|

Beveling End Treatment Round Heat Exchange Steel Tube Material For Heat Transfer |

|

Customized Length Exchanger Steel Tube With Galvanized Coating And High Performance |

|

Heat Exchanger Steel Tube With Chamfering End Treatment Wall Thickness 0.7-30MM |

|

Customized Length Round ST37 Heat Exchanger Tube The Dependable Choice for Heat Transfer |

|

Customized Length Heat Exchanger Steel Tube in 0.7MM-30MM Wall Thickness for Various Applications |