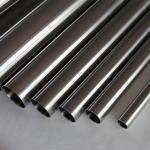

ASTM B111Heat Exchanger Copper Nickel Tube / Pipe C71500 DNV / BIS

/ API / PED Quick Details| Standard: | ASTM, AISI, DIN, EN | Place of Origin: | Shanghai, China (Mainland) | Brand Name: | TOBO | | Model Number: | COPPER NICKEL TUBE | Type: | Seamless | Steel Grade: | COPPER NICKEL TUBE | | Application: | Heat Exchanger, Heat Exchanger | Certification: | ISO | Welding Line Type: | ERW | | Thickness: | 0.5-8mm | Outer Diameter: | 6-101.6mm | Product Type: | cuni tube | | Finish: | Annealed | Technical: | Cold Drawn | Material: | COPPER NICKEL | | Certificate: | ISO | Qualtiy: | HIGH | Package: | Wooden Case | | Ship: | By Sea | Place: | Shanghai China |

Packaging & Delivery| Packaging Details: | POLY WOODEN CASE | | Delivery Detail: | 30 DAYS |

Product Type:heat exchanger cuni tube

We have of sales offices in most major centres in India. Copper

Nickel Alloy Tube also knowns as Cupro Nickel Tube or Cuni Tubing,

it has a Tensile Strength (annealed) of 52000 psi (359 MPa) and it

has a Tensile Strength (rolled-H04 for flat products/ hard

drawn-H80 for tubing) of 78000 psi (538 MPa). Alloy of copper and

nickel is called Copper Nickel tubing and it has very high

resistance to corrosion in seawater. Though cuni finned tubing has

similar corrosion resistance to that of copper, it has better

fatigue strength and superior general strength. Because of its

characteristics, such Cupro Nickel Seamless Tube is used in

offshore fire water systems, evaporators used in power stations,

cabled tubes for pneumatic lines and hydraulic lines and in

cylinder cores in high-quality locks. The Thermal Expansion Co-efficient of Copper Nickel Seamless Tubing

(@20-300°C/68-572°F) is 9.00 µin/in °F (16.2 µm/m °C). Cu-Ni Tubes

has an Elastic Modulus (C71500 annealed) of 22000 ksi (152 GPa).

Copper nickel alloy tube chemical composition is Cu 71.25-76.5, Fe

≤ 0.20, Pb ≤0.050, Mn ≤ 1.0, Ni 23.5-26.5 and Zn ≤ 1.0. Copper

Nickel Welded Tube has a Thermal Conductivity of 32.9 W/mK (0.0900

BTU in/hr.ft². °F) and it has a Rockwell B Hardness of 69. ASME

SB466 Cupro Nickel Tube has superb formability, making for ease of

bending and flaring. It offers trouble-free installation, longer

life and it exhibits characteristics of reliability and safety. In

the 19th century, jackets of bullets were coated with Copper

nickel. At low temperatures, it has excellent thermal conductivity

and as such it is used in a wide number of cryogenic applications.

It is also used in heat exchangers, fasteners, feedwater heaters,

silver-colored circulation coins, jewelry and in boat hulls. | Trade Name | UNS | Copper Nickel Industry Specifications | Chemical Composition | Min.Tensile

(KSI) | Min.Yield

(KSI) | Elongation

% | | CuNi 90/10 | UNS C70600

UNS C70620 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543

ASTM B111, B122, B151, B171, B359, B395, B432, B466, B467, B543,

B608 DIN 2.0872 MIL C-15726, T-15005, T-16420, T-22214 SAE J461,

J463 | Cu 88.6 min

Pb .05 max*

Fe 1.8 max

Zn

1 max*

Ni 9-11 max

Mn 1.0 max | 38 | 15 | 30 | | CuNi 90/10 | UNS C7060X | EEMUA 144 90/10, 145 90/10, 14 90/1 | Cu rem.

Pb .01 max

Fe 1.5-2.0

Zn 0.2 max

P 0.2 max

S 0.2 max

Ni 10-11

Mn 0.5-1.0 | 40 | 15 | 30 | | CuNi 70/30 | UNS C71500

UNS C71520 | ASME SB111, SB171, SB359, SB395, SB466, SB467, SB543

ASTM B111, B122, B151, B171, B359, B395, B432, B467, B543, B552,

B608, F467, F468

DIN 2.0882

MIL C-15726, T-15005, T-16420, T-22214

SAE J461, J463 | Cu rem (65.0 min)

Pb .05 max*

Fe 0.4-1.0

Zn 1 max*

Ni 29-33

Mn 1 max | 52 | 18 | 45 | | CuNi 70/30 | UNS C71640 | ASTM B111, B543, B552 | Cu rem

Pb .05 max*

Fe 1.7-2.3

Zn 1 max*

Ni 29-32

Mn 1.5-2.5 | 63 | 25 | –

|

|