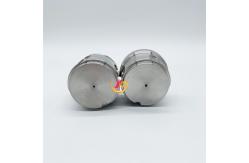

35ml zirconium milling jars comfort in retach ball mill

|

|

35ml zirconium milling jars comforty in Retsch ball mill

The Zirconia oxide grinding jar have been developed especially for extreme test conditions such as high sample throughput and high mechanical stress. Features include.

35ml zirconium oxide jar for RETSCH MIXER MILLS

TYPICAL SAMPLE MATERIALS

For example, waste, soil, chemical products, coated tablets, drugs, ores, grain, tissue, glass, hair, ceramics, bones, plastics, alloys, minerals, oil seeds, plants, sewage sludge, pills, textiles, wool etc.

Highly polished YSZ (Yttrium stabilized ZrO2) zirconium oxide jars, 60 times hardness of regular steel, highly wear-resistant and resistant to acid and solvents. The grinding jars are extensively applied on in the fields of Paint, Ink,Coating, Geology, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, Environmental Protection and so on. Each jar set includes grinding jar, jar lid, rubber sealing gasket and different sizes of mixed zirconium oxide grinding balls.

We have mass-produced various types of ball mill jars for Retsch and Fristch from Germany brand.

Retsch grinding jar: 50ml,80ml,125ml zirconium oxdie, agate, tungsten carbide grinding jar for Retsch planetary bal mill PM100,PM200,PM 400; 25ml,35ml,50ml zirconia oxide ,tungsten carbide jars for Retsch Mix mill MM 500; 50ml,100ml,250ml and 500ml zirconia oxide and tungsten carbide for Retsch vibratory disc ball mill RS200

Fritsch grinding jar: 250ml and 500ml zirconia,alumina,agate grinding jar for Fritsch P6.

We have inventory of all the above ball mill jars. Just let us talk more!

Technical indicators for Zirconia Ball mill jar

Dimesion for our regualar avaliable zirconia mill jar

(offer OEM & ODM Service)

Note 1: Jar size of each patch will control

tolerance ±0.1-0.2mm. 2:One set includes: jar + lid +

rubber sealing gasket. Choice of Grinding Jars & Grinding BallsIn order to prevent excessive abrasion, the hardness of the grinding jars used and of the grinding balls must be higher than that of the material used. Normally, grinding jars and grinding balls of the same material should be chosen.

Features of Zirconium oxdie grinding jar: 1. High specific gravity, high efficiency 2. Highly wear resistant to acid and solvents 3. High cost-effective, low wear and long lifetime 4. Highly polished, smooth, easy to clean, low abrasion to the equipment 5. High mechanical strength, good toughness, impact resistance, no broken beads 6. Mainly used for lab planetary ball mill machines Image of 25ml and 35ml zirconium mill jar with stainless steel casing price for Retsch MIXER MILLS

Packaging & Shipping

Application Fields:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Industrial Zirconium Milling Jars Industrial Ceramic Processing Zirconium Milling Jars 35ml Zirconium Milling Jars | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Industrial Ceramic 100ml Zirconium Oxide Ball Mill Jar With Zirconia Grinding Mortar For RETSCH VIBRATORY DISC MILL |

|

Retsch Grinding Jars 100ml Tungsten Carbide Ceramic Parts for disc mill |

|

100ml Tungsten Carbide Jar for Retsch VIBRATORY DISC MILLRS 200 Durable Material |

|

Tungsten Carbide Grinding set supplier for retsch ball mill |

|

50ml Tungsten Carbide TC Milling Jars for Retsch VIBRATORY DISC MILLRS 200 |

|

35ml Tungsten Carbide Ball Grind Jars For retsch ball mill mm400 and MM 500 Vario |