Industry Robot Arm For IRB 6650S Robotic Welding 0.04mm Repeatability

|

Industry Robot Arm for IRB 6650S robotic weldingIn the world of industrial automation, the ABB IRB 6650S stands out as a high-performance industry robot arm specifically designed for robotic welding. With its precision, speed, and durability, the IRB 6650S is transforming welding processes across industries such as automotive, aerospace, and metal fabrication. This article explores the features, benefits, and applications of the IRB 6650S, showcasing why it is a top choice for robotic welding.

High Precision The IRB 6650S offers exceptional repeatability (±0.06mm), ensuring consistent weld quality. High Speed Optimized for fast cycle times, this industry robot arm significantly increases productivity. Durability and Reliability Built to withstand harsh industrial environments, the IRB 6650S ensures long-lasting performance with minimal maintenance. Flexibility The 6-axis design allows for complex welding paths, enabling the robot to handle intricate welding tasks with ease. Integrated Welding Solutions The IRB 6650S is compatible with a wide range of welding equipment, including arc welding and spot welding systems. Energy Efficiency ABB’s energy-efficient designs help reduce operational costs and environmental impact. As industries continue to embrace automation, ABB robot arms like the IRB 6650S will play an increasingly important role in robotic welding. Innovations such as AI, machine learning, and IoT integration will further enhance the capabilities of these robotic systems, paving the way for smarter and more efficient welding processes.

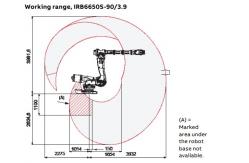

The ABB IRB 6650S is a robust and versatile industry robot arm optimized for robotic welding. Key specifications include: Payload Capacity: Up to 125 kg (including welding equipment). Reach: 2.55 meters (standard), with options for extended reach. Axes: 6-axis design for maximum flexibility. Technical Parameters:

FAQ: *Q:Why are we? A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period.

*Q:How about our service concept? A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection.

*Q:What products can we offer? A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling.

*Q:Why you purchase from us? A:You don’t worry about after-sales problem to cooperation with us.

About us Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college. |

||||||||||||||||||||

| Product Tags: IRB 6650S Industry Robot Arm 0.04mm Repeatability Industry Robot Arm Robotic Welding Industry Robot Arm |

|

Kuka Kr 20 3 Industrial Robotic Arm automated Material Handling |

|

Pick & Place Robot Industrial Kuka KR 120 R2700 Automation Solutions |

|

Kuka Iiwa 14 R820 Robot Arm Seven Axes Multi-joint Automation |

|

Robot Abb 6700 Industrial Robotics Applications in Automotive |

|

KR 1000 1300 Titan Pa Heavy-duty Six-axis KUKA Robot Collision Avoidance |

|

Abb Irb 760 4-axis Robot Full Layer Palletizing Material Handling |