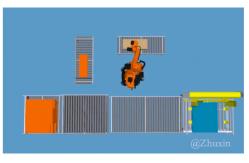

How To Integrate Palletizers With Robot Simulation Software KUKA kr180pa

|

How To Integrate Palletizers With Robot Simulation Software KUKA KR180paIn the fast-paced world of industrial automation, integrating palletizers with robot simulation software is a critical step toward optimizing efficiency and precision. Whether you’re working with KUKA, ABB, or other industrial robots, this process ensures seamless operation, reduces downtime, and enhances productivity. 1. Why Integrate Palletizers with Robot Simulation Software? Integrating palletizers with simulation software offers numerous benefits:

2. Step-by-Step Guide to Integration Step 1: Choose the Right Simulation Software Select a simulation software compatible with your palletizer and robot system. Popular options include:

Step 2: Import Robot and Palletizer Models Import 3D models of your robot and palletizer into the simulation software. Ensure the models are accurate to reflect real-world conditions. Step 3: Configure the Palletizing Process Define the palletizing parameters, such as:

Step 4: Simulate and Optimize Run simulations to test the palletizing process. Identify bottlenecks or inefficiencies and adjust parameters accordingly. Step 5: Validate and Deploy Validate the simulation results by comparing them with real-world data. Once optimized, deploy the program to your robot system. 3. Key Considerations for Successful Integration

The main components and functions of the equipment are introduced

FAQ: *Q:Why are we? A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period. *Q:How about our service concept? A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection. *Q:What products can we offer? A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling. *Q:Why you purchase from us? A:You don’t worry about after-sales problem to cooperation with us. About us Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college. |

||||||||||||||||||||||||||||||||

| Product Tags: 380V industrial robot cell three phase industrial robot cell 380V robotic palletizer cell |

|

Payload 120kg Service Mode Robot Welding Cell with Online Support |

|

Abb Palletizing Robot Price IRB660 Four Axis Multi-station Palletizing |

|

Robotic Palletizers Palletizing Systems For Every Application |

|

Food Industrie Palletizing KR60-3 Kuka Industrial Robots Perfect Solution |

|

KR C4 Controller Equipped Robot Food Technology KUKA KR60-3 Industrial Robot Cell |

|

The Kr60-3 Transport Robot Carries A Payload Of 60kg 2033 Arms Long |