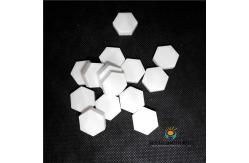

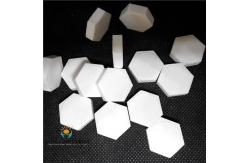

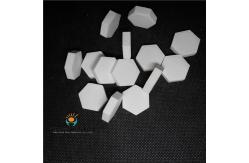

Hexagon Ceramic Tile

Introduction

There are all kinds of shapes for instance square shape, rectangle

shape, trapezoid and some special shape. lt is the ideal

wear-resistant materials for wear resistant grinding equipment such

as oil, chemical, mine, steel and electricity industry.

Hexagon ceramic tile is excellent for application of high impact

and extreme wear. The alumina provides a very smooth surface for

material flow and actually reduces its resistance to friction with

service life. The elastomer backing also helps to reduce vibration

and noise levels within the plant and is engineered to resist the

size and type of impact experienced for each individual project.

Characteristic

1. High hardness: Generally, the hardness is greater than 80 or

more, and the highest can reach more than 92;

2. Good wear resistance: at least 200 times that of ordinary carbon

steel and 10 times that of high-chromium cast iron;

3. Light weight: the specific gravity of alumina is generally only

about 3.6, that of silicon carbide is about 2.7, and that of

zirconia is about 6;

4. Good heat resistance: The heat resistance of different

wear-resistant ceramics is not the same, but this product is used

in the occasion of resistance to particle erosion, and there is no

problem with heat resistance.

Founction

Hexagon ceramic tile is mainly used in a variety of equipment for

conveying various high hardness and high abrasive granular

materials, including electricity, heat, steel, coal, cement,

mining, smelting, petroleum, building materials, chemicals, fans,

paper, machinery, powder Coal conveying, material conveying system,

pulverizing system, ash discharge, dust removal system and other

mechanical equipment in industries such as body engineering, grain

machinery, and tobacco. Depending on the combination with the metal

substrate, it can be used on the inner surface of stationary parts,

such as pipes, elbows, separators, chutes, valves, various shells,

etc., and can also be used on high-speed rotating equipment, such

as various fans. Rotors, impellers, rollers, etc.

Technical data

| ceramic size | ceramic tites are available from 10*10mm to 100*150mm,tickness of

ceramic tiel can be from 1.5 to 50mm | |

| backing plate | steel palte with thickness ranging from 3mm to 10mm(potional) |

| rubber thickness | depends upon the impact stress expected or customer requirement. |

| remark | metal +rubber + ceramic/rubber + ceramic |

| plan surface or spherical surface. studs also available upon

request |

| custom shapes can be made |

Photos