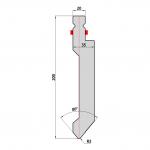

LS106 CNC Punch Press Brake For Hydraulic Bending Machine

|

|

LS106 CNC Press Brake Punch For Hydraulic Bending Machine Sheet Press Brake Tooling

Product Description

Press brake tooling: Bending machines rely on press brake tooling to achieve accurate sheet metal bending and forming. The tooling comprises punches, dies, guide rails, die holders, and etc. With diverse sizes and styles available, such as the popular Amada style, Wila and Trumpf style, and Euro style, the tooling can be easily adapted to different bending machine brands.

How to choose a tool you need:

Standard Tools 2. Provide the total length, angle, sharp R, die height, etc 3. The mold that needs to be divided can be divided into dimensions Special Forming Tools 1. Provide the cross section shape drawing of product workpiece 2. Provide bending machine manufacturer, machine tonnage, machine length and other relevant data. 3. Provide product material, plate thickness and other data. 4. Put forward product requirements (such as scratch, R angle size, parallelism, straightness) 5. Provide product materials (for mold test) 6. If there is any difficulty in selecting the mould, please consult us.

Company Show

FAQ 1. Are you a manufacturer or a trading company? We are a manufacturer.

2. Can you put my brand name (logo) on these products?

5. What is the Minimum Order Quantity (MOQ) for your OEM/ODM

service? |

||||||||||||||||||||

| Product Tags: CNC Punch Press Brake LS106 Punch Press Brake Hydraulic Bending Machine Punch Press Brake |

|

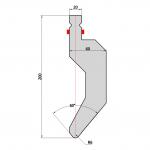

WAL237.90.R1 Wila Type Custom 90 Degree Press Brake Punch |

|

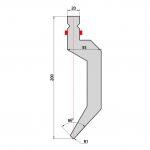

WAL237.90.R06 European Type Press Brake Punch 90 Degree |

|

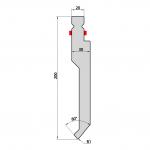

LS10.66 Quicklock Press Brake Punch 80 Degree |

|

LS10.65 Quicklock Press Brake Punch 80 Degree 42CrMo |

|

LS10.63 Quicklock Press Brake Punch 86 Degree High Hardness |

|

LS10.62 Quicklock Press Brake Punch 80 Degree Induction Hardening |