Printing grade polycarbonate film is a versatile and

high-performance thermoplastic material used extensively in various

industries for its excellent balance of properties. Here are

specification and some key features and applications: The specifications of printing grade polycarbonate film: | Property | Specification |

|---|

| Thickness | 0.2 mm to 1.5 mm | | Transparency | 85% to 92% light transmission | | Haze | Less than 1.0% | | Size | 915mm*1820mm | | Impact Strength | 600 to 850 J/m (Notched Izod) | | Tensile Strength | 60 to 70 MPa | | Elongation at Break | 100% to 150% | | Heat Resistance | Continuous use temperature up to 120°C | | Melting Point | 220°C to 230°C | | Chemical Resistance | Resistant to many oils, solvents, and chemicals | | Electrical Insulation | Dielectric strength: 15 to 30 kV/mm | | Surface Energy | 38 to 42 dyne/cm (can be enhanced with surface treatment) | | Moisture Absorption | 0.15% to 0.30% (24 hours at 23°C) | | UV Resistance | Can be enhanced with UV protective coating | | Printing Compatibility | Screen Printing, Digital Printing, Thermal Transfer |

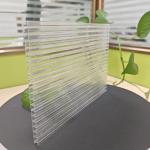

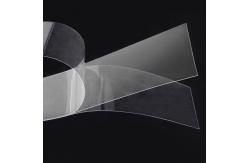

Key Features:Optical Clarity: - High transparency with excellent light transmission.

- Low haze and high gloss finish.

Durability: - High impact resistance.

- Good dimensional stability.

- Resistant to cracking and breaking.

Thermal Resistance: - Wide operating temperature range.

- Good heat resistance, making it suitable for various printing

processes.

Chemical Resistance: - Resistant to many chemicals, oils, and solvents.

Electrical Properties: - Good electrical insulation properties.

Surface Quality: - Smooth and uniform surface, ideal for printing.

Applications:Graphics and Printing: - Used in overlays, labels, nameplates, and control panels.

- Suitable for screen printing, digital printing, and thermal

transfer printing.

Electronics: - Used in membrane switches, touch screens, and displays.

Automotive: - Instrument panels and interior components.

Industrial Applications: - Used in control panels, machine covers, and protective barriers.

Printing Techniques:Screen Printing: - Popular for its durability and vibrant colors.

- Suitable for high-volume production runs.

Digital Printing: - Offers high-resolution prints.

- Ideal for short runs and custom designs.

Thermal Transfer Printing: - Provides durable and resistant prints.

- Commonly used for barcodes and labels.

Considerations:- Ink Adhesion: Polycarbonate film requires proper surface treatment to enhance

ink adhesion. Pre-treatment methods like corona treatment or

applying an adhesion promoter are often used.

- Compatibility: Ensure that the inks and printing methods are compatible with

polycarbonate to avoid issues like smudging or poor adhesion.

- Environmental Factors: Consider the operating environment, as exposure to UV light or

harsh chemicals can affect the longevity of printed graphics.

-

Printing polycarbonate film's Producstion and Package and

Delivery |