High Strength Electrical Switch Boxes Custom Bending Stamping Works Enclosure

|

|

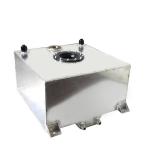

Custom Bending Stamping Works Enclosure Box Processing Parts with Tolerance ±0.01mm

Product Paramenters

Product display Surface Treatment

Anodizing: Primarily used for aluminum electrical switch boxes. Anodizing forms an oxide layer on the surface of aluminum, increasing its surface hardness and corrosion resistance. Anodized surfaces typically have a metallic luster and are more wear and corrosion-resistant than untreated aluminum.

Application

Used in indoor and outdoor equipment of electrical,railway,vessel,engineering etc..

About us

With over 10 years’ experience in the field. Our Precision Machining, innovative, with an unique design and superior quality, are suitable for any kind of medical, automotive, consumer goods, aerospace, energy, and robotics. and will meet your needs.

With a massive R&D environment, Pusher took advantage of market-leading technology and introduced various of advanced equipment to guarantee the rigorous quality in production.

Product Packaging

Why choose PUSHER ?

Professional production team and sale team.

FAQ

4. What are your terms of delivery?

5. Do you test all your goods before delivery?

Certificates |

||||||||||

| Product Tags: High Strength Electrical Switch Boxes Custom Bending Electrical Switch Boxes |

|

Carbon Steel 3D Printer Sheet Metal Parts Designed To Meet Your Customization Needs |

|

Customized Color Sheet Metal Fabrication Welding Stamping Metal Electronic Enclosures |

|

Customized Size Electrical Switch Boxes With Anodizing And Powder Coating |

|

Fabrication Carbon Steel Metal Bending Parts Designed To Your Exact Requirements |

|

Customized Carbon Steel Fabrication Parts Designed To Meet Your Requirements |

|

Customizable Electrical Switch Boxes Portable Horizontal Aluminum Fabrication Laser Cutting |