Sheet Metal Fabrication And Assembly Electrical Switch Boxes By Laser Cutting

|

|

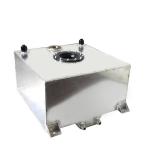

Customized Color Sheet Metal Fabrication and Assembly with Sample by Laser Cutting

Product Paramenters

Product display Surface Treatment

Anodizing: Primarily used for aluminum electrical switch boxes. Anodizing forms an oxide layer on the surface of aluminum, increasing its surface hardness and corrosion resistance. Anodized surfaces typically have a metallic luster and are more wear and corrosion-resistant than untreated aluminum.

Application

Energy Sector: In power plants, transmission lines, and substations, electrical switch boxes control and protect power transmission systems.

About us

PUSHER also has advanced inspection equipment, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we can supply the high-quality castings to our customers and make products meeting comprehensive inspection requirements on chemical composition, mechanical properties, non-destructive testing, and high precise dimensional inspections.

Product Packaging

Shipment

Why choose PUSHER ?

Professional production team and sale team.

FAQ

Q: How can I get a quotation?

Certificates |

||||||||||||

| Product Tags: Laser Cutting Electrical Switch Boxes Laser Cutting Metal Electrical Boxes |

|

Carbon Steel 3D Printer Sheet Metal Parts Designed To Meet Your Customization Needs |

|

Customized Color Sheet Metal Fabrication Welding Stamping Metal Electronic Enclosures |

|

Customized Size Electrical Switch Boxes With Anodizing And Powder Coating |

|

Fabrication Carbon Steel Metal Bending Parts Designed To Your Exact Requirements |

|

Customized Carbon Steel Fabrication Parts Designed To Meet Your Requirements |

|

Customizable Electrical Switch Boxes Portable Horizontal Aluminum Fabrication Laser Cutting |