The Application and Considerations of Hard Anodizing in CNC Part

Processing

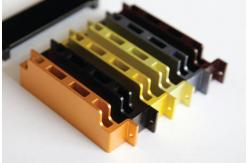

Hard anodizing is a surface treatment process that significantly

enhances the durability and functionality of CNC-machined parts. It

involves the electrochemical formation of a hard, wear-resistant

oxide layer on the surface of the workpiece. This layer not only

improves the part's corrosion resistance but also increases its

hardness and scratch resistance.

In CNC part processing, hard anodizing finds extensive application

in industries that require high-performance components, such as

automotive, aerospace, and medical manufacturing. By withstanding

extreme environments and heavy usage, hard-anodized parts can

maintain their integrity and performance over longer periods.

However, there are certain considerations that need to be taken

into account when using hard anodizing in CNC part processing.

Firstly, the material selection is crucial. Aluminum and its alloys

are commonly used for hard anodizing as they respond well to the

process. Other materials may not produce satisfactory results.

Secondly, the surface preparation of the workpiece is essential.

Any impurities, oils, or contaminants on the surface can interfere

with the anodizing process, leading to inconsistent or defective

oxide layers. Therefore, thorough cleaning and pretreatment steps

are necessary to ensure a smooth and uniform oxide layer formation.

Furthermore, the anodizing process itself requires precise control

of various parameters, such as electrolyte composition,

temperature, and voltage. These factors directly influence the

thickness, hardness, and quality of the oxide layer. It is crucial

to conduct careful process optimization and quality control to

achieve the desired results.

Lastly, post-treatment considerations should also be taken into

account. After hard anodizing, the parts may require sealing or

polishing to further enhance their properties or aesthetics.

Additionally, regular maintenance and inspection of the anodizing

equipment are necessary to ensure consistent and reliable results.

In conclusion, hard anodizing is a powerful surface treatment

technique that significantly improves the durability and

performance of CNC-machined parts. However, it requires careful

consideration of material selection, surface preparation, process

control, and post-treatment steps to achieve optimal results. By

adhering to these considerations, hard anodizing can be effectively

utilized in various industrial applications, enhancing the quality

and longevity of CNC-machined components.