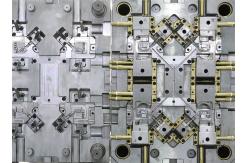

automotive air intake grille injection mould with harden steel

The plastic automotive air intake grille is a crucial component in

the automotive industry, serving to protect the engine and regulate

airflow. The production of this component relies heavily on

precision injection molding, which requires a mold that meets

specific requirements and addresses certain challenges.

Firstly, the injection mold for the air intake grille must possess

exceptional precision. The intricate details and contours of the

grille, including its openings and louvers, must be accurately

replicated in the mold to ensure a perfect fit and optimal airflow.

This demands meticulous design and machining of the mold cavity to

achieve the desired shape and dimensions.

Furthermore, the mold material must be able to withstand the high

temperatures and pressures encountered during the injection molding

process. It must also exhibit excellent wear resistance to maintain

its precision over time. The selection of appropriate mold material

is crucial to ensure the long-term stability and performance of the

mold.

One of the main challenges in producing the air intake grille is

the achievement of a smooth and uniform surface finish. Any

imperfections or defects in the mold can lead to visible marks or

scratches on the final product, compromising its aesthetic appeal

and functionality. Therefore, the mold must be carefully polished

and finished to ensure a smooth surface that translates into a

high-quality grille.

Another challenge lies in the complexity of the grille's design.

The air intake grille often features intricate patterns and

contours that not only enhance its appearance but also serve

specific engineering purposes. The mold must be able to accurately

capture these details while maintaining the integrity of the

structure. This often requires advanced mold design techniques and

the use of complex machining processes.

Moreover, the production of the air intake grille involves the use

of thermoplastic materials that require specific processing

conditions. The mold must be designed to accommodate the material's

flow characteristics and shrinkage behavior, ensuring consistent

and repeatable results. This involves careful consideration of the

injection points, gating systems, and cooling channels within the

mold.

In conclusion, the production of plastic automotive air intake

grilles requires precision injection molds that meet strict

requirements and address various challenges. By utilizing advanced

mold design techniques, selecting appropriate mold materials, and

carefully controlling the injection molding process, manufacturers

can produce high-quality grilles that meet the demands of the

automotive industry.