Telephone houseing injection mould with texture on mould surface

and high quality standard

The telephone housing is a crucial element that not only protects

the internal components but also contributes to the overall

aesthetics and user experience of the device. Depending on the type

of telephone, the housing can vary significantly in design,

material, and functionality.

When it comes to telephones, there are several classifications

based on their usage and features. For instance, we have

traditional fixed-line telephones commonly found in households and

offices, cordless phones for added convenience and freedom of

movement, and smartphones, which are now an integral part of our

daily lives. Each of these telephones requires a specifically

designed housing that meets their unique requirements.

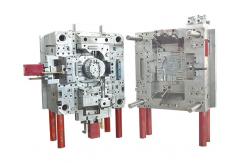

The injection mold is the key to producing these precision-crafted

telephone housings. The mold is designed to replicate the desired

shape, dimensions, and features of the housing, ensuring a perfect

fit and seamless assembly. The material used for the mold must be

able to withstand the high temperatures and pressures involved in

the injection molding process while maintaining its structural

integrity over time.

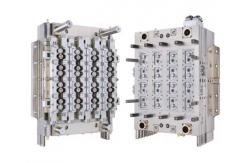

The surface treatment of the telephone housing mold is also

crucial. It not only enhances the aesthetic appeal of the final

product but also improves its durability and functionality. Common

surface treatments include painting, polishing, and texturing.

Painting can provide a smooth and attractive finish, while

polishing can give the housing a sleek and shiny appearance.

Texturing, on the other hand, can provide a more grippable surface,

making it easier to hold and use the telephone.

Moreover, the material chosen for the housing is equally important.

Plastics are a popular choice due to their durability, lightweight,

and cost-effectiveness. However, different plastics have different

properties, and the choice of material depends on the specific

requirements of the telephone. For instance, some plastics offer

better scratch resistance, while others have better chemical

resistance.

In conclusion, the telephone housing and its corresponding

injection mold are integral parts of the manufacturing process. The

precision and quality of these components directly impact the

performance, durability, and overall user experience of the

telephone. By carefully selecting the right materials, designs, and

surface treatments, manufacturers can create telephone housings

that not only meet the functional requirements but also exceed

customers' expectations.