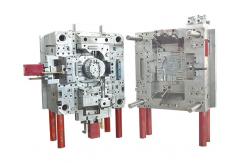

Mirror-finish polishing of injection molding dies is an intricate

process that demands meticulous attention to detail and a profound

understanding of materials, machining, and molding techniques. This

highly specialized process ensures not only the aesthetic

perfection of the final product but also its functional integrity

and production efficiency.

The steel material chosen for the mold is the foundation of the

mirror-finish process. It must possess a unique balance of

machinability, hardness, and corrosion resistance. High-grade

stainless steels and specialty alloys are often selected due to

their ability to maintain a smooth and reflective surface even

under high temperatures and pressures encountered during the

injection molding process. The selection of steel also impacts the

polishing time and the ease with which a mirror finish can be

achieved.

The polishing process itself is a multi-step journey that begins

with rough grinding and progresses through progressively finer

abrasives and polishing compounds. Each step requires careful

monitoring and adjustment to ensure that the surface remains free

from scratches, pits, or other imperfections. Modern polishing

equipment, combined with skilled operators, enables precise control

over the polishing forces and speeds, resulting in a uniform and

defect-free mirror finish.

CNC machining precision is another crucial aspect of mirror-finish

mold production. High-precision CNC machines are capable of

creating intricate mold geometries with micron-level tolerances.

This precision ensures that the mold's surface is smooth and

continuous, ready for the polishing process. Advanced CAD/CAM

software is often utilized to design and simulate the machining

process, allowing for the optimization of tool paths and cutting

conditions for maximum precision and efficiency.

The cooling system, or "waterways," within the mold is another

essential component. Proper cooling is critical for maintaining the

structural integrity of the mold and ensuring consistent product

quality. The design of the waterways must take into account the

mold's geometry, the injection material, and the desired production

rate. Effective cooling systems minimize thermal deformation,

reduce cycle times, and improve the overall efficiency of the

injection molding process.

The injection molding parameters, including injection pressure,

temperature, and speed, must be carefully calibrated to match the

specific requirements of the mirror-finish mold. These parameters

directly influence the flow and solidification of the molten

plastic within the mold, affecting the final product's surface

quality and mechanical properties. It is essential to strike a

balance between ensuring complete filling of the mold cavity and

minimizing stress and deformation during the cooling phase.

In addition to the above-mentioned factors, the maintenance and

care of the mirror-finish mold are also critical. Regular cleaning

and inspection of the mold, along with timely replacement of

worn-out components, are essential for maintaining the quality and

performance of the mirror finish.

In conclusion, mirror-finish polishing for injection molding dies

is a comprehensive and demanding process that requires a synergy of

high-grade steel, precision machining, optimized cooling systems,

and carefully calibrated injection molding parameters. A

well-executed mirror-finish mold not only enhances the aesthetic

appeal of the final product but also ensures its functional

integrity, optical performance, and efficient production

capabilities. With the continued advancements in materials,

machining techniques, and injection molding technology,

mirror-finish polishing will continue to evolve, delivering

ever-higher standards of quality and efficiency in the

manufacturing industry.