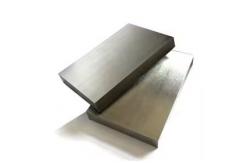

Hastelloy B-2 Sheets/Blocks Nickel Based CNC Machining Parts Cold Rolling

|

|

Hastelloy B-2 Sheets/Blocks Nickel Based CNC Machining Parts Cold Rolling

Nickel alloy machined plates refer to nickel alloy plates that have been mechanically processed (such as cutting, drilling, milling, turning, etc.). They have excellent corrosion resistance, high temperature resistance and mechanical properties. These machined boards are suitable for a variety of industrial scenarios, especially in applications that require materials to remain stable in extreme environments. Here are some applicable scenarios: Chemical and petrochemical industry: used to manufacture containers, pipes, flanges, valves and pumps, etc. These equipment are often exposed to chemicals and corrosive fluids.

Specification:Grade: UNS: N10665; W. Nr./EN: 2.4617 ASTM: B 333, B 335, B 619, B 622, B 626, B 366 ASME: SB-333, SB-335, SB-619, SB-622, SB-626, SB-366 NACE: MR0175 Features:

Physical Properties: Density: 0.333 lb/in3 Electrical Resistivity: 824 Ohm-circ mil/ft

Mechanical Properties: Average Tensile Data, Sheet and Plate

DINGSCOHunan Dinghan New Material Technology Co., Ltd. (DINGSCO) specialized in Nickel Based Corrosion Resistant and High Temperature alloys products which used in the world’s most technically demanding industries and applications.We are dedicated to providing our customers with best quality products, fastest possible deliveries, most competitive prices of Nickel Based Corrosion Resistant and High Temperature alloys in bars, rods, forged flanges, valve parts (Ball, Stem, Seat Ring, etc), forged shapes (shafts, discs, blocks, hubs, rings, cylinders and other custom shapes) according to ASTM, ASME, API, AMS, NACE and other industry standards.

PROFESSIONAL NICKEL ALLOY MANUFACTURER

CORE VALUE

CUSTOMIZED PRODUCTS:

APPLICATION:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Hastelloy B-2 CNC Machining Parts Nickel Based CNC Machining Parts CNC Machining Parts Cold Rolling |

|

Precision Customized Mechanical Parts Nickel Alloy Forgings INCONEL 625 |

|

Hastelloy B-2 Sheets/Blocks Nickel Based CNC Machining Parts Cold Rolling |

|

Nickel Alloy Aviation Forgings Inconel Monel Incoloy Hastelloy Alloy OEM Design |

|

API 6A Nickel Alloy 718 Tubing Hanger Types For Petroleum / Gas Extraction |

|

Custom Nickel Alloy Channel Inconel 600 UNS N06600 Forged U Channel C Channel |

|

INCONEL 625 Valve Ball Customized Nickel Alloy Machining Parts Valve Parts |