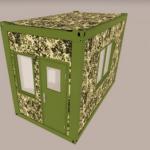

Prefeb Quick Assembly Customizable Detachable Container House

As a wholly-owned subsidiary of Wujiang Saima (established in

2005), Suzhou Stars Integrated Housing Co., Ltd. focuses on foreign

trade. As one of the most professional prefabricated house

manufacturers in south-east China, we provide customers with all

kinds of integrated housing solutions.

Equipped with complete production lines, including sandwich panel

production machines and steel structure production line, with 5000

square meter workshop and professional staff, we already built

long-term business with domestic giants like CSCEC and CREC. Also,

based on our export experience in the past years, we are furthering

our steps to global customers with best product and service.

As a supplier to overseas customers all over the world, we are very

familiar with the manufacturing standards of various countries,

such as European standards, American standards, Australian

standards, and so on. We have also participated in the construction

of many large-scale projects, such as recent 2022 Qatar World Cup

camping construction .

Detachable container houses offer several advantages: - Flexibility: Detachable container houses are designed to be easily

assembled and disassembled, offering flexibility in terms of

relocation. This means that they can be moved and reassembled at

different locations as needed, making them suitable for temporary

housing, remote work sites, or situations where mobility is

required.

- Scalability: Modular container houses can be easily expanded or

downsized by adding or removing modules. This scalability allows

for adjustments based on changing needs, such as accommodating a

growing family or downsizing when fewer living spaces are required.

- Quick Assembly: Similar to other container housing options,

detachable container houses can be assembled quickly using

prefabricated components. This rapid assembly process reduces

construction time and labor costs, making them an attractive option

for emergency housing or rapid deployment situations.

- Customization: Detachable container houses can be customized to

meet specific design preferences and requirements. Modular

construction allows for flexibility in layout, size, and

configuration, with options for adding features such as windows,

doors, insulation, and interior finishes.

- Cost-effectiveness: Modular container houses are often more

cost-effective than traditional construction methods. They require

less material and labor for assembly, resulting in lower

construction costs. Additionally, their modular nature allows for

efficient use of resources and reduced waste.

- Durability: Detachable container houses are made from durable

shipping containers, which are designed to withstand harsh

environmental conditions. They are resistant to wind, water, and

fire damage, providing a safe and secure living environment for

occupants.

- Sustainability: Repurposing shipping containers for housing helps

reduce waste and environmental impact by giving new life to

materials that would otherwise be discarded. Additionally, modular

container houses can be designed to be energy-efficient, with

features such as solar panels, rainwater harvesting systems, and

energy-efficient appliances.

Overall, detachable container houses offer a practical and

sustainable solution for affordable housing, emergency shelters,

and temporary accommodation needs, with the added benefits of

flexibility, scalability, and quick assembly.

| Standard Quick Assembly Container House Datasheet | Product Specification:

3-meter standard container | Length(mm) | 5950(5730) | | Width(mm) | 3000(2800) | | Height(mm) | 2800(2500) | | Center column | | | Roof | Flat roof, free drainage | | Number of floors | ≤3 | | Design parameters | Service life | 5-8 years | | Ground live load | 1.8KN/㎡ | | Roof live load | 0.5KN/㎡ | | Wind load | 0.6KN/㎡ | | Seismic degree | 8 | | Structural | corner column | galvanized cold rolled section steel, t=2.3mm, material Q235B | | roof main beam | galvanized cold rolled section steel, t=2.3mm, material Q235B | | roof sub-beam | Galvanized square steel 5*5, t=1.5mm, radian galvanized square

steel 4*6t= 1.2mm material Q235B | | floor main beam | galvanized cold-rolled section steel, t=2.3mm, material Q235B | | floor sub-beam | galvanized square steel 4*8 (5), galvanized square steel 8*8 (4)

material Q235B | | Paint | Graphene Powder spraying (Electrostatic spraying) | | Roof | Roof panel | 0.40mm thick color steel plate, color white gray | | Ceiling | 0.25mm thick 811 ceiling, color white gray | | Floor | Decorative surface | | | basic floor | 18mm sanding board | | Wall | Thickness | 50mm thick color steel glass fiber sandwich board; The outer and

inner plates are made of 0.3mm aluminum plated zinc color steel

plate | | Heat preservation | 50mm thick glass silk wool, bulk weight ≥60kg/m³, combustion

performance is class A non-combustible | | Color | white gray PE coating | | Door | Spec(mm) | Width X height =920*2030 common door | | Material | Steel door | | Window | Spec(mm) | Front window: width X height =920*1200; Rear window (standard) :

width X height =920*1200; | | Frame | Plastic steel window single glass | | Glass | common | | Electricity | Voltage | 220V~250V | | Wire | input power wire is 4 square, AC wire is 4 square, socket wire is

2.5 square, lighting switch wire is 1.5 square | | Circuit breaker | High break Miniature Circuit breaker (32A) | | Lamp tube | Two sets of circular LED fluorescent lamps | | Socket | 3 five-hole socket 10A, 1 three-hole air conditioning socket 16A |

|