Product Description:

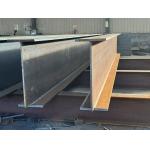

Non-galvanized H-beam is a high-quality steel with a unique

H-shaped cross-section. Its shape is like the letter "H", with two

parallel flanges connected vertically to a thick web, which gives

it excellent mechanical properties.

In terms of material, non-galvanized H-beam usually uses

high-quality carbon structural steel or low-alloy high-strength

steel. Through advanced rolling technology, the internal structure

of the steel is ensured to be uniform and dense, giving it good

strength and toughness.

In terms of size specifications, non-galvanized H-beams are of

various types, with web heights ranging from tens of millimeters to

hundreds of millimeters, and flange widths and thicknesses are also

available in a variety of options to meet the diverse needs of

different projects. Its cross-sectional dimensions are precise,

flat, and the surface is smooth, without obvious cracks, scars,

folds and other defects, providing reliable guarantees for

subsequent processing and use.

Although not galvanized, non-galvanized H-beam retains the metallic

luster of the steel itself and presents a silver-gray texture. This

natural surface state has unique advantages in certain application

scenarios that do not require high appearance but focus on cost

control and original steel performance.

Features:

- Product Name: Non-Galvanized H Beam Retaining Wall

- Weather Resistance: Excellent

- Service: Bending, Welding, Uncoiling, Cutting, Punching

- Installation: Solar Panel Support

- Used For: Bridge Fence Posts, Highway Fence Posts, Airport Fence

Posts

- Application: Industrial Construction, Bridge Construction,

Machinery Manufacturing, Marine Resource Development Projects, Etc.

- Keywords: H steel for retaining walls

Technical Parameters:

| Attribute | Value |

|---|

| Surface Treatment | Non-Galvanizing |

| Used For | Bridge Fence Posts, Highway Fence Posts, Airport Fence Posts |

| Service | Bending, Welding, Uncoiling, Cutting, Punching |

| Material | Non-Galvanized Steel |

| Installation | Solar Panel Support |

| Application | Industrial Construction, Bridge Construction, Machinery

Manufacturing, Marine Resource Development Projects, Etc. |

| Standard | Aisi |

| Grade | Q235B, G250, G300, S275JR, S355JR |

| Size | Customizable |

| Weather Resistance | Excellent |

Applications:

Industrial plant: In the construction of industrial plants,

non-galvanized H-shaped steel is widely used in the frame structure

of the plant. Its strong bearing capacity can easily support the

weight of the roof and wall of a large plant, ensuring the

structural stability of the plant during long-term use. Since

industrial plants usually have relatively low requirements for

aesthetics, non-galvanized H-shaped steel can effectively reduce

costs while meeting structural requirements. For example, some

large machinery manufacturing plants, logistics warehouses, etc.

use non-galvanized H-shaped steel to build frames, which is not

only durable but also economical.

Small bridges: For some rural bridges or pedestrian overpasses with

small spans and relatively small traffic flow, non-galvanized

H-shaped steel can be used to make the beam structure of the

bridge. Its high strength and good toughness can meet the bearing

requirements of the bridge in daily use, and since it does not

require galvanizing, it can reduce the construction cost of the

bridge. For example, in the construction of rural road bridges in

some remote areas, the application of non-galvanized H-shaped steel

not only ensures the quality of the bridge, but also meets the

local economic budget.

Temporary bridges: In some construction sites or emergency rescue

projects, temporary bridges need to be built to meet traffic needs.

Non-galvanized H-beam has become a common material for temporary

bridges due to its easy processing, convenient installation and low

cost. It can quickly build a stable bridge structure, providing

convenience for engineering construction or emergency rescue.

Support and Services:

The Non-Galvanized H Beam Retaining Wall product is designed to

provide a strong and durable solution for soil retention and

stabilization in a variety of applications. Our technical support

team is available to assist with any questions or concerns

regarding the installation and use of our product. Our services

include:

- Consultation on design and engineering of retaining walls

- Assistance with material selection and calculations

- On-site support during installation

- Maintenance and repair services

We pride ourselves on our commitment to customer satisfaction and

our expertise in the field of retaining wall systems.

Packing and Shipping:

Product Packaging:

- The H beam retaining wall product will be securely packed in a

wooden crate.

- The wooden crate will be lined with protective materials to prevent

any damage during transportation.

- The product will be labeled with its name, size, and weight for

easy identification.

Shipping:

- The product will be shipped via a reliable courier service.

- Shipping fees will be calculated based on the destination and

weight of the product.

- The estimated delivery time will be communicated to the customer

upon purchase.