Making Foam Machine XPE XLPE IXPE EVA Internal Mixer Kneader Foam

Machinery

XPE Foam Internal Mixer is a tipping bucket pressurized

internal mixer with fast production speed, stable temperature

control, and uniform mixing. It is suitable for mixing dozens of

raw materials such as various rubber, plastics, color

masterbatches, etc., and provides a variety of models for customers

select.

- The mixing chamber, rotor, pressure weight and other components are

all jacketed, which can be heated or cooled by medium, steam, heat

transfer oil and water to meet various rubber (plastic) refining

process requirements. The quality of processed materials is

excellent and stable.

- The spiral angle and working length of the rotor ridges are

reasonably designed to achieve the best kneading effect. The rotor

ridges and end faces are cladding wear-resistant hard alloy. The

surfaces of the mixing chamber, rotor and pressure weight that are

in direct contact with the materials are all stainless steel, which

are polished, bright, wear-resistant and corrosion-resistant.

| Model Item | Unit | EKKOFLEX-75L |

Total Mixing Capacity | L | 75 |

Drive Motor Power | KW | 110 |

Flip Motor Power | KW | 4 |

Flip Angle | . | 140 |

Cooling Water Pressure | Mpa | 0.3-0.4 |

Compressed Air Pressure | Mpa | 0.5-0.8 |

Rotor Speed(F/R) | r/min | 38/30.5 |

Output | Kg/h | 80-350 |

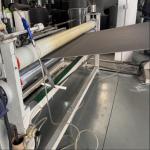

Detailed Photos:

Internal Mixing Unit

FAQ:

Q1:What plastic foaming machines could you provide?

Internal mixer machine, Granulation machine, XPE foam extrusion

machine,

XLPE Horizontal foaming furnace, IXPE Vertical foaming furnace,

Embossing machine,

Foam laminating machine, Foam thicking machine, Glue coating

machine, PE slicing machine.

Q2:What kind of services can you provide?

We are specialized in manufacture the XPE/IXPE Foaming equipment,

in addition to installation and setup the production line, our

service also includes provide raw material formula, process

parameters and other technical services to the buyer freely.

Q3:Is there any vulnerable parts? How to do if the vulnerable parts

damaged?

Yes, there are vulnerable parts. We provide you enough quantity of

spare parts, these spare parts will ship to you with machines

together.

Q4:Could you customize the plastic foaming machine?

Yes, Of course.