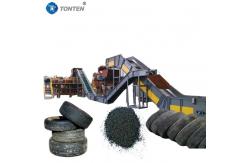

Used Tire Shredder Recycling Machine Price Tire Recycling

Production Line

Product introduction:

The tire shredder recycling production line can crush waste tires

or rubber products into rubber particles and powder, realizing the

recycling and reuse of waste rubber. Through the tire shredder

recycling production line, rubber powder and rubber particles can

be collected, and steel wire and fiber can be separated from

rubber.The waste tire rubber powder equipment consists of a waste

tire cutting ring mouth machine, a strip and block cutting

integrated machine, a roller mill, a dual magnetic separator, a

cyclone feeding machine, a screening machine, a single magnetic

separator, an automatic conveyor, and a distribution cabinet. Small

footprint, low failure rate, strong mobility, high degree of

automation, the entire equipment can be operated by only 1-2

people. The machine can be customized for you according to

capacity, final product, etc.Finished product can be used for the

construction of sports plastic sports fields and amusement park

facilities, and rubber floor tiles, plastic lawn filling particles

such as football field, swaterproof rolls, waterproof coatings and

other items can also be made using rubber powder.

Features:

1. The raw material is a whole tire. After processing, the steel is

completely separated, the fiber separation rate can reach more than

99%, the yield rate is high, and the market competitiveness is

strong

2. The tire crushing and recycling production line has a high

degree of automation and requires less labor.

3. The tire is granulated into fine rubber particles of 40~120

mesh, and the steel and fiber are completely recovered at room

temperature.

4. It can be pressed into blocks and burned as fuel, and can be

further processed into higher quality particles, used as

reinforcing agents, fillers or masterbatches in the plastic and

rubber industries, and can be used to produce rubber pads, rubber

belts, soles, etc.

5. The efficient rotary screen ensures that the material is

separated from other debris and removes metal wires, etc.

Equipped with a water cooling system, the finished rubber powder

will not clump; equipped with semi-automatic and fully automatic

options,can be matched according to customer requirements.

Tire shredder recycling parameters:

No. | Type | Motor power | Quantity |

1 | tire circle cutter | 4kw | 1 set |

2 | automatic strip cutting and blocking machine | 30kw | 1 set |

3 | roller milling machine | 35kw+3kw+1.5kw | 1 set |

4 | steel wire separator machine | 1.5kw | 1 set |

5 | screening machine | 2.2kw | 1 set |

6 | magnetic separator equipment | 0.75kw | 1 set |

7 | output | 3kw+1.5kw | 1 set |