Joint Bearing: Wear-Resistant, Flame-Resistant, Tear-Resistant,

Heat-Resistant, Cold-Resistant INDRON® joint bearings of self-lubricating material are

suitable for guide-vane bearings and connecting-rod bearings of

tubular turbines.

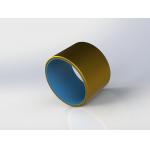

Compared with regular copper-based mosaic graphite bearings,

INDRON® guide-vane, connecting-rod and regulating-ring bearings

have larger contact area and no lubricating oil is required,. The

metal-based cladding can effectively protect shaft necks from wear

and tear. INDRON® guide-vane, connecting-rod and regulating-ring

bearings can effectively cushion the vibration resulting from

opening and closing of a guide vane and avoid cracking upon

impacts.

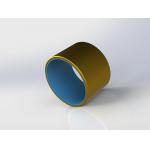

Rigid, tough and wear-resistant, suitable for impulsive and

vibrating loads, maintenance-free; Bonding of long-termed lubricative particles, stable lubricating

effects, low friction and wear; Effective protection of the shaft neck due to full coverage of the

shaft neck; A homogeneous self-lubricating material with reliable performances.

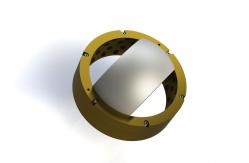

| Material Grade | | Bearing(lining) | INDRON®TSTN | INDRON®HRBR | INDRON®HAWF | INDRON®UNIV | INDRON®PLAT | | Material | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers | SyntheticEngineering Elastomers | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers | | Recommended Workplace | Guide Bearings & Seals | Guide Bearings& Seals | Guide Bearings & Seals | Guide van, connecting rod bushing | Guide vane, connecting rod bushing | | Temperature Limit | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | | Dry Rub | Yes | low speed | low speed | Yes | Yes | | Acid Resistance | limit | limit | limit | limit | limit | | Alkaline Resistant | limit | limit | limit | limit | limit | | Hydrocarbon Suitability | Yes | Yes | Yes | Yes | Yes | | Abrasion Resistance | good | excellent | excellent | good | good | | Friction Pair(bushing) | bronze | HRC40 | HRC40 | HRC40 | HRC40 | | Stainless | recommend | recommend | recommend | recommend | | Typical Application | water, sea water | water, sea water | water, sea water | water, sea water | water, sea water | | Most fluids(pH 5-10) | Most fluids(pH5-10) | Most fluids(pH5-10) | Most fluids(pH 5-10) | Most fluids(pH5-10) | | Note | Lowest coefficient of friction,suitable for dry running

applications, good wear resistance | Use silt water under moderate grinding conditions | Use ofsilt-containing water under high grinding conditions.

Contains abrasion resistant | high load capacity | high load capacity |

|