Product Description: Ensure the highest level of protection for sterile medical devices

with our advanced Medical Grade Composite Packaging Film.

Designed to meet stringent industry standards, this high-barrier

film provides exceptional resistance to moisture, oxygen, and

contaminants, ensuring long-term sterility and integrity of

sensitive medical products. Constructed from a multi-layer composite material, this film offers

superior puncture resistance, tear strength, and heat-sealability,

making it ideal for sterilization processes (such as ethylene

oxide, gamma irradiation, or steam autoclaving). Its low

particulate shedding and FDA-compliant composition

make it safe for direct contact with medical instruments, implants,

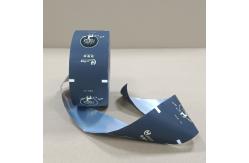

and pharmaceutical products. Suitable for pouches, blister packs, and sterile barrier

systems, this film is compatible with automated packaging

machines for efficient, high-speed production. Product Parameters:| Attribute | Specification |

|---|

| Material Composition | Multi-layer composite (PET/PE/AL/PP or customizable) | | Thickness | 80–200 microns (customizable) | | Width | 100–800 mm (customizable) | | Roll Length | 300–3,000 meters (customizable) | | Core Diameter | 76 mm (3") or 152 mm (6") | | Color | Transparent, Tyvek®-coated, or printed options | | Key Features | - High oxygen & moisture barrier (≤0.1 cc/m²/day OTR, ≤0.1

g/m²/day WVTR)

- Puncture & tear-resistant

- Compatible with EtO, gamma, and steam sterilization

- Low particulate & non-toxic | | Sterilization Methods | Ethylene Oxide (EtO), Gamma Irradiation, Steam Autoclave | | Oxygen Transmission Rate (OTR) | ≤0.1 cc/m²/day (ASTM D3985) | | Water Vapor Transmission Rate (WVTR) | ≤0.1 g/m²/day (ASTM F1249) | | Peel Strength | 1–10 N/15mm (adjustable) | | Certifications | FDA 21 CFR, ISO 11607, ASTM F1980, REACH, RoHS | | Applications | Sterile medical device packaging, surgical kits, implants,

diagnostic equipment |

|