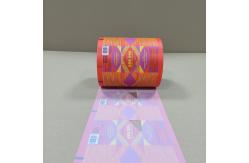

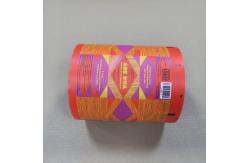

Our Premium Customizable Multi-Layer Soap Packaging Film is designed to provide superior protection and visual appeal for

soap and personal care products. Featuring a high-barrier,

multi-layer structure, it effectively blocks moisture, oxygen, and

odors, preserving the quality, fragrance, and shelf life of your

soaps. The film is highly customizable, allowing tailored

dimensions, designs, and printing to meet your brand’s unique

needs. Ideal for bulk orders, it combines durability with

moisture-proofing performance, ensuring safe storage and

transportation while enhancing product presentation. Made from

food-grade, eco-friendly materials, it complies with global safety

standards, making it a reliable choice for both functional and

aesthetic packaging solutions.

Specifications

| Item | Details |

|---|

| Structure | Multi-layer co-extruded film | | Layers | Customizable layer configuration (e.g., barrier layer, sealant

layer, print layer) | | Materials | Polyethylene (PE), Polypropylene (PP), Ethylene-Vinyl Alcohol

(EVOH), Metallized layers (optional), and other food-grade polymers | | Barrier Performance | - Oxygen Transmission Rate (OTR): Low (customizable based on layer

composition)

- Water Vapor Transmission Rate (WVTR): Low (moisture-proofing

design) | | Thickness | 20–100 microns (customizable) | | Width | Customizable (standard ranges: 100–1500 mm) | | Length | Customizable (roll format for industrial use) | | Customization | - Dimensions: Tailored to packaging requirements

- Printing: Gravure, flexo, or digital printing (up to 10 colors)

- Surface Treatment: Matte/gloss finish, embossing, holographic

effects | | Key Features | - High barrier against moisture, oxygen, and volatile compounds

- Excellent sealability and puncture resistance

- Temperature resistance: -40°C to +80°C (standard); extended

ranges available upon request

- Eco-friendly options: Recyclable, biodegradable, or compostable

materials (available as upgrades) | | Applications | Soap bars, detergent blocks, bath bombs, and other solid personal

care products | | Compliance | Meets FDA (USA), EU 10/2011, and global food contact safety

standards |

|