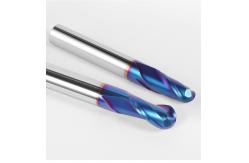

CNC High Precision Milling Cutter For Steel Cutting KM-65 Series

|

High Precision KM-65 Series CNC Milling Cutter For Steel CuttingProduct Description

Product Parameters It can meet different processing conditions and processing forms of

customers and has a wide range of Instructions for use 1. Before using the tool, please measure the tool runout. If the tool accuracy exceeds 0.01MM, please correct it before cutting. 2. The shorter the tool extends from the chuck, the better. If the tool extends longer, the speed, feed speed or cutting amount should be reduced. 3. During cutting, if abnormal vibration or sound occurs, please reduce the speed and cutting amount until the situation improves. 4. Spray and jet cooling are preferred for steel cooling, which can improve the use effect of the milling cutter. Product display Company Introduction

Factory display

FAQ |

||||||||||||||||

| Product Tags: CNC High Precision Milling Cutter Steel High Precision Milling Cutter | ||||||||||||||||

|

Diamond Coating 4 Flute Solid Carbide End Mill for High Precision Metal Milling |

|

Solid Carbide Graphite Deep Groove Round Nose End Mill for General High Speed Cutting |

|

Diamond Coating 4F Flute CNC Router Bits for Graphite Cutting Precision |

|

4F Flutes Round Nose Milling Cutter Diamond Coated Solid Carbide End Mill for High Precision Graphite CNC Cutting Tools |

|

Carbide Milling Cutter End Mill for Graphite , 4 Flutes Endmill with Diamond Coating |

|

HRC70 Graphite Corner Radius Milling Cutter Tungsten Carbide Corner Radius End Mill CNC Mechanical Processing Center Tool |