Stabilize Pipe Wall Thickness Gravimetric Dosing System Connect

Extruder

1.Product Introduction

Gravimetric Dosing System: Real-time control, high precision,

continuous measurement, adaptive algorithm for stabilizing wall

thickness.By controlling the meter weight of pipe,adjusting the

extruder screw speed and haul off speed to achieve the goal of

stabilizing production prpcess.

2.Main Components

| Data Acquisition Control Unit | Collecting data of meter weight in any time |

| Screw Speed Acquisition Unit | Adopting the extruder's screw speed |

| Display Control Unit | Inputting and providing changes of data to oprator to check |

| Acquisition Unit for Linear Speed | Adopting the haul off speed |

3.Features

- Adaptive algorithm

- Real-time control of pipe meter weight

- Improved production quality

- Versatile application

4.Profits

- Gravimetric Dosing Systems provide high levels of accuracy and

precision in material dosing. They use load cells or weighing

scales to measure the weight of the material being dosed in

real-time. This ensures that the exact amount of material is

dispensed, leading to consistent and reliable results.

- Gravimetric Dosing Systems continuously monitor the weight of the

material being dispensed, allowing for real-time control and

adjustment. This dynamic control ensures that any variations in

material properties or flow rates are immediately compensated for,

maintaining accurate dosing even under changing conditions.

- By accurately dosing materials, gravimetric systems help optimize

the overall process efficiency. They minimize material waste and

reduce the need for rework or corrections due to over or

under-dosing. This leads to cost savings and improved productivity.

5.Applications

The Gravimetric Dosing System is applicable for HDPE pipe and other

plastic pipe raw materials in granular etc.

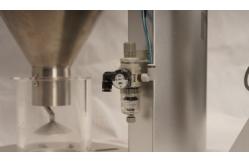

6.Way of installation

Installing Gravimetric Dosing System with an

adapter on the extruder,also please don't forget to set the holder

to hold system,and set a hopper to feeding materials.

7.On-sight Application

8.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise pursuing "Product is a work of art". We have set high

standards for product design, internal management, and quality

control.

Achieving a highly intelligent workshop in the future

is the trend of factories in the future, and it is also the parent

goal for Worth to strive for. Worth products focus on helping users

achieve automation throughout the production process, from

improving product quality and saving raw materials to reducing the

dependence on labor throughout the process.

Since extablished in 2009,in these 14 years, we have

participated in plastic and rubber exhibitions in

China and other countries such as

Vietnam,Thailand,America,England etc. We are cooperating with

over 800 companies like DEMUKA,GSM etc, and establishing long-term

cooperative relationships with them.