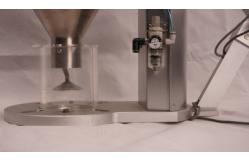

Feeding Raw Material In Granules Gravimetric Dosing Feeder For Plastic Pipe Control

|

|

Feeding Raw Material In Granules Gravimetric Dosing Feeder For

Plastic Pipe Control Gravimetric Dosing Feeder is a type of feeding system that accurately dispenses material by weight. This type of feeder is commonly used in facilities that require precise material handling, such as in the plastic pipe industry.

5.Applications

Q1. What is your terms of packing? A: Generally, we pack our plastic granule gravimetric dos in wooden cases.

A:T/T or some other payment methods.We'll show you the photos of the products and packages before you pay the balance.

Q4.Will you test the machine before exporting? A:Yes,of course |

||||||||

| Product Tags: Granule Gravimetric Dosing Feeder Raw Material Gravimetric Dosing Feeder Plastic Pipe Control Gravimetric Feeder |

|

PPR Pipe Extrusion Gravimetric Feeder For Extrusion Control Meter Weight |

|

Gravimetric Weighing Extrusion Line Gravimetric Dosing Unit For Plastic Granules |

|

HDPE LDPE PPR Pipe Gravimetric Dosing System Raw Materials In Granular |

|

Feeding HDPE Materials Gravimetric Doser Plastic Pipe Extruder CE Standard |

|

Granular Material For Plastic Pipe Gravimetric Feeder Control Extruder Screw Speed |

|

Plastic Pipe Gravimetric Dosing System HDPE PPR PE Granules Extrusion Line |