Feeding Powder With Twin Screw Feeder Setting In Extrusion

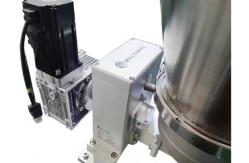

1. Product Introduction

WalthMac WPB series Twin Screw Feeder mainly suitable for powdered raw materials, precise feeding of materials can be

used independently or in combination.

2.System Principle

Based on the weighing principle, when the weighing mechanism gets

the actual feeding amount in per unit time, it will compare the

actual feeding quantity with the set feeding amount. If there is a

deviation, the screw speed of the feeder will be adjusted to ensure

that the actual value matches the set value.

3.Parameter

| The Application for Material | Powdery,Granular,Flake |

| Weighing resolution | 1/4000 |

| Drive unit | Servo drive |

| Display unit | 7''/10'' inch touch screen |

| Communication interface | Available for multiple industrial fieldbus |

4.Features

- Only applicable for powder

- Use widely in building material,chemicals,cable,food and others

- Multiple screw types to choose

- The precision of feeding and blending are meet the international

standard

5.Profits

- Prevent material congestion in the machine

- Twin screw makes powder be blend fully

- Stainless steel won't reflect with material

- Feeding error ratio is not more than 0.5%

6.Applications Scope

Generally speaking Twin Screw Feeder is suitable for the

manufactures who using masterbatch, additive,powder or other

auxiliary materials in the process of producing will get much

assistance by Twin Screw Feeder.

7.Way of installation

Installing the Tein Screw Feeder on the platform on

the extruder,the materials will release from the hose.

8.On-sight Application

9.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise pursuing "product is art". We have set high standards

for product design, internal management, and quality control.We

have passed CE,ISO,UNGM certifications and have served over 800

companies which are our long-term cooperator in the world.

Achieving a highly intelligent workshop in the future

is the trend of factories in the future, and it is also the parent

goal for Worth to strive for. Worth products focus on helping users

achieve automation throughout the production process, from

improving product quality and saving raw materials to reducing the

dependence on labor throughout the process.

Since extablished in 2009,in these 14 years, we have

participated in plastic and rubber exhibitions in

China and other countries such as

Vietnam,Thailand,America,England etc. We are cooperating with

over 800 companies like DEMUKA,GSM etc, and establishing long-term

cooperative relationships with them.